Supplier & Stockist EN 10149-2 S900MC Steel Sheet, 900 MC Plate In India

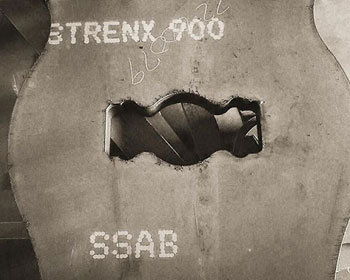

S900MC High Yield Structural Steel Plates is made up of a structural steels that has very high strength and abrasion resistant properties. The steels belongs to a family of steels that are known for the applications in high wear and tear conditions. The High Yield Structural Steel 900 Plates were known as domex 900 plates prior to rebranding. Suryadeep Industry is a leading Distributor and supplier of these plates in different scales and standards. The standards for 900 Structural Steel Plates are EN 10051, EN 10149-2 and EN 101163-2. The plates come in varying sizes with thicknesses ranging from 3mm to 10mm and width up to 1600mm and length up to 13000mm. The S900MC Steel Plates is hot rolled and is readily available for cold forming. The high performance also results from the cold forming ability of the plates. They can last longer with less damage.

The High Yield Structural Steel 900 MC Plus Sheets have very high strength with 900MPa minimum yield strength and 930 to 1200MPa minimum tensile strength. The strength makes the sheets applicable in some high stress and stronger applications. The 900 High Strength Steels Plates are used in conveyors, tanks, containers and platforms of high friction and abrasive materials. Structural applications such as bridges and building constructions also use the 900 MC EN 10149-2 Hot-Rolled Structural Steel Plates in varying application requirements. The chemical composition of the material has titanium, vanadium, niobium, aluminum, silicon, sulfur, phosphorus and carbon. The composition along with the hot rolling process makes the 900 Structural Plates strong. The plates are supplied with a mill finish. Applications such as the chemical industries, petrochemical industries, refineries and pulp and paper production plants also use the Structural Steel 900 Plates for the extended lifespan and the abrasion resistance properties. We supply the plates in cut to lengths and custom dimensions as well. The Steel 900 MC Plates is one of the very high performing steels plates in the market and please contact us for any inquiries on the EN 10163-2 900 MC Hot-Rolled Heavy Plates and their pricing.

Table of Content - S900MC Plus Steel Sheets Most Common Specification - S900MC Steel Plate Chemical Resistance Guide - High Yield Structural S900MC Steel Plate Mechanical Properties Analysis - High Yield 900MC Steel Plate Application - 900 Structural Plate - Most Commonly Used S900MC High Yield Structural Steel Plate Types - S900MC Grade D/E Sheet Impact Properties - Equivalent Grades Of S900 MC Sheet - 900 MPa Coils Tolerances - S900 Plates Plasma Cutting - Laser Cutting for Hig Yeild 900 Structural Steel Plate - S900 MC Sheet Cutting Mathod - 900 Structural Plate Maximum Preheat Levels - S900MC Steel Plate Typical Tensile Strength - Steel 900 MC Plate Typical Properties - 900 High Strength Steel Plates Solid Cemented Carbide Drill - S900MC Plus Sheets Indexable Insert Drill - 900 Plate Drills With Exchangeable Drill Heads - S900 MC EN 10149-2 Hot-Rolled Structural Steel Plate Thickness - S900MC High Yield Structural Steel Plate Physical Properties - S900MC Plates Preheat And Interpass Temperatures

S900MC Plus Steel Sheets Most Common Specification

| Item | 900 / 900MC / 900 Plus Plate |

| Standards | EN 10149-2, EN 10051, EN 10163-2 |

| Material | S900MC |

| Thickness | 4 - 100 milimeter |

| Width | Up to 3350 milimeter |

| Length | Up to 14630 milimeter |

Check S900MC Plus Steel Sheets, High Yield Structural Steel 900 Plate Chemical Composition, S900MC Steel Plate, 900 MC Plus Structural Steel Plates Equivalent, Specification Of 900 Structural Steels Plate.

S900MC Steel Plate Chemical Resistance Guide

| S | C | Cr | Si1 | Cu | Mn | Mo | P | Ni | B |

| 0.020 | 0.20 |

0.80 | 0.50 |

0.3 | 1.60 | 0.70 | 0.020 | 2.0 | 0.005 |

1) Sum of Nb, V and Ti = max 0.22%

High Yield Structural S900MC Steel Plate Mechanical Properties Analysis

| Thickness | Yield strength R p0.2 | Tensile strength Rm | Elongation A 5 |

| 4.0 - 53.0 | 900 | 940 - 1100 | 12 |

| 53.1 - 100 | 830 | 880 - 1100 | 12 |

High Yield 900MC Steel Plate Application

Get High Yield Structural S900MC Plate At Best Price, Physical Properties Of S900MC Hot-Rolled Structural Steels Plate, We provide 900 Plus High Strength Steel Plates, Steel 900 MC Plate Expert Cutting Service In Bhopal, India.

- Construction

- Oil & Gas Suryadeep

- Load-bearing Structures

- Refineries Suryadeep

- Paper Suryadeep

- Chemical Suryadeep

- Petrochemical Suryadeep

900 Structural Plate

| USED | DIMENSIONS | STANDARDS |

|---|---|---|

Structural Low temperatures (down to -60°) |

T: 4 - 100 mm W: Up to 3350 mm L: Up to 14630 mm |

EN 10025-6 EN 10029 EN 10163-2 |

Most Commonly Used S900MC High Yield Structural Steel Plate Types

Get a Live Quote Now For 900 MC Plus Sheets, We provide 900 High Strength Steel Plates, EN 10163-2 900 MC Hot-Rolled Heavy Plates 3rd Party Testing And S900 EN 10025-6 Sheets Expert Cutting Service In Bhopal, India.

High Yield Structural Steel 900 Plates

High Yield Structural Steel 900 Plates

High Yield Structural 900 MC Sheet

High Yield Structural 900 MC Sheet

S900MC Plus Steel Sheets

S900MC Plus Steel Sheets

S900MC Plate

S900MC Plate

S900MC Steel Plate

S900MC Steel Plate

900 Structural Steel Plate

900 Structural Steel Plate

High Yield Structural S900MC Steel Plate

High Yield Structural S900MC Steel Plate

S900MC Hot-Rolled Structural Steel Plate

S900MC Hot-Rolled Structural Steel Plate

900 Plus High Strength Steel Plates

900 Plus High Strength Steel Plates

S900 MC Plus Sheets

S900 MC Plus Sheets

900 High Strength Steel Plates

900 High Strength Steel Plates

S900 EN 10025-6 Steel Sheets

S900 EN 10025-6 Steel Sheets

S900MC Grade D/E Sheet Impact Properties

| Grade | Min impact energy, transverse test, Charpy V 10x10 mm tests specimens2) |

Meet Requirements For |

|---|---|---|

| 900 F | 27 J/ - 60 0C | S890QL1 |

| 900 E | 27 J/ - 40 0C | S890QL |

Equivalent Grades Of S900 MC Sheet

We Maintain S900MC High Yield Structural Steel Plate, S900 Plate Good Quality, 900 MC EN 10149-2 Hot-Rolled Structural Plate Supplier In Bhopal, India, Check Availability Of 900 Structural Plate, Get Free Quote Of Structural 900 Plates, S900 MC Plus Steel Plates.

| Thickness(mm) | 4.0 - 80.0 | 80.1 - 100.0 |

|---|---|---|

| CET(CEV) | 0.39 (0.58) | 0.41 (0.63) |

900 MPa Coils Tolerances

- Thickness : Guarantees meets the requirements of EN 10 029 Class A, but offers narrower tolerances.

- Length and Width : According to Structural dimension program. Tolerances conform with EN 10 029 or to Structural standard after agreement.

- Shape : structural offers tolerances according to EN 10 029.

- Flatness : Tolerances according to Flatness Guarantee Class C, which are more narrow than EN 10 029 Class N.

- Surface Properties : According to EN 10 163-2 Class A, Subclass 3.

- Bending : Tolerances according to Bending Guarantee Class B.

S900 Plates Plasma Cutting

| Cutting method | Kerf width | HAZ | Dim. tolerances |

|---|---|---|---|

| Plasma cutting | 2-6.5 mm | 2-5 mm | ± 1.0 mm |

Laser Cutting for Hig Yeild 900 Structural Steel Plate

| Cutting method | Kerf width | HAZ | Dim. tolerances |

|---|---|---|---|

| Laser cutting | < 1 mm | 0.2-2 mm | ± 0.2 mm |

S900 MC Sheet Cutting Mathod

| Cutting method | Kerf width | HAZ | Dim. tolerances |

|---|---|---|---|

| Oxy-fuel cutting | 2-5 mm | 4-10 mm | ± 2.0 mm |

900 Structural Plate Maximum Preheat Levels.

| Material | Max preheating temp. (°C) |

|---|---|

| S900MC | 300 |

S900MC Steel Plate Typical Tensile Strength

| TYPE OF STEELS | TYPICAL TENSILE STRENGTH (MPa) |

|---|---|

| S900MC, 900 MC, 900 PLUS | 1010, 1150, 1060 |

Steel 900 MC Plate Typical Properties

| Hardness in Brinell (HBW) |

Hardness in Rockwell (HRC) |

Tensile strength, / Rm (N/mm2) |

|

|---|---|---|---|

| S900MC | ~300 | ~29 | ~935 |

900 High Strength Steel Plates Solid Cemented Carbide Drill

| S900MC | ||

|---|---|---|

| Vc (m/min) | 60-90 | |

| fn (mm/rev) | min-max | |

| Diameter | 3.0-5.0 | 0.03-0.06 |

| 5.01-10.0 | 0.06-0.12 | |

| 10.01-15.0 | 0.12-0.18 | |

| 15.01-20.0 | 0.18-0.24 | |

S900MC Plus Sheets Indexable Insert Drill

| S900MC | ||

|---|---|---|

| Vc (m/min) | 80-140 | |

| fn (mm/rev) | min-max | |

| Diameter | 12.0-20.0 | 0.04-0.10 |

| 20.01-30.0 | 0.06-0.12 | |

| 30.01-44.0 | 0.06-0.14 | |

| 44.01-63.5 | 0.08-0.16 | |

900 Plate Drills With Exchangeable Drill Heads

| S900MC | ||

|---|---|---|

| Vc (m/min) | 60-90 | |

| fn (mm/rev) | min-max | |

| Diameter | 7.5-12.0 | 0.08-0.13 |

| 12.01-20.0 | 0.13-0.22 | |

| 20.01-25.0 | 0.22-0.27 | |

| 25.01-33.0 | 0.27-0.36 | |

S900 MC EN 10149-2 Hot-Rolled Structural Steel Plate Thickness

| THICKNESS (t) (mm) | ALONG ROLLING DIRECTION MINIMUM Ri/t | DIE OPENING WIDTH (W) MINIMUM W/t | ||

|---|---|---|---|---|

| HOT ROLLED STRIP | S900 MC | 3 ≤ t ≤ 8 t > 8 |

3.0 3.5 |

12 12 |

| S900MC PLUS | 3 ≤ t ≤ 6 | 3.0 | 12 | |

S900MC High Yield Structural Steel Plate Physical Properties

| Temperature (°C) |

Modulus of elasticity (GPa) |

Mean coefficient of thermal expansion 10-6/(°C) between 20(°C) and | Thermal conductivity (W/m·°C) |

Specific thermal capacity (J/kg·°C) |

Specific electrical resistivity (Ω mm²/m) |

Density (kg/dm³) |

Poisson’s coefficient, ν |

|---|---|---|---|---|---|---|---|

| 31 | - | - | 0.13 | - | |||

| 217 | 435 | - | 24.3 | 142 | - | ||

| 477 | - | 24 | 42.2 | 124 | 233 |

S900MC Plates Preheat And Interpass Temperatures

| Grade | Thickness(mm) | CEV1) % Typical | CET1) % Typical |

| Strenx 900 MC | 3- 7.9 | 0.50 | 0.25 |

| 8-10 | 0.53 | 0.27 | |

| Strenx 900 Plus | 3- 6 | 0.50 | 0.34 |

| Grade | Sheet thickness | Max interpass |

| (mm) | temperature, °C | |

| Strenx 900 MC | 3– 10 | 100 |

| Strenx 900 Plus | 3- 6 | 150 |