S650MC Grade D/E Plate, 650 MPa Coils Supplier In Bhopal, India

High Yield Structural 650 MC Sheet is a high performing abrasion resistant steels sheet that is made by hot rolling but is good for cold forming. The sheets are used in high stress environments such as the automobile industrial engines and in engineering applications. The S650MC High Yield Structural Steel Plates are also used in other industries where the friction, wear and tear and the abrasion of the application is high and demands for a high strength steels plates. Suryadeep Industry is a leading Distributor and supplier of these High Yield Structural Steel S650MC Plates in large quantities. The sheets belong to different standards such as the EN10149-2, EN 10051 and EN 10163-2. The 650 Structural Steel Plates width ranges up to 1600mm, the thickness ranges from 2mm to 10mm and the length ranges up to 16000mm.

The High Yield Structural S650MC Steel Plates also has a high strength with 650MPa minimum yield strength and 700 to 850MPa minimum tensile strength. This high strength makes it applicable in heavy machineries, aerospace industrial structures and in engine parts. The High Yield Structural Steel 650 Sheets are also used in the construction industry, chemical industry and in petrochemical industries. The high strength and hardness result from the chemical composition and the hot rolling process of the High Yield Structural 650 MC High Strength Plates. The material includes carbon, silicon, manganese, phosphorus, sulfur, aluminum, niobium, vanadium and titanium in the composition. The 650MC EN 10149-2 Hot-Rolled Structural Plates comes in mill finish condition for application in different industries. High war and tear applications such as the pulp and paper mills used the EN 10163-2 650 MC Hot-Rolled Heavy Plates for rollers, conveyors and in storage systems. These plates are also used in excavator buckets, linings of heavy machineries and in other highly wearing parts. The MPa 650 MC Plates was formerly known as the Domex steels brand. Please forward your inquiries on the High Yield Structural S650 EN 10051 Steels Sheets towards us.

Table of Content - 650 High Yield Structural Coils Grade Standard And Specification - High Yield Structural 650 MC Plates Chemical Compatibility - 650MC High Yield Structural Steel Sheets Mechanical Properties Analysis - Most Commonly Used S650MC High Yield Structural Steel Plate Types - S650MC Grade D/E Plate - Equivalent Material Of High Yield Structural Steel S650MC Plates - 650MC Structural Steel Plates Tolerances - 650 MPa Coils Plasma Cutting - S650MC Grade D/E Plate Laser Cutting - High Yield Structural 650 MC Plates Cutting Mathod - S650MC Steel Plate Typical Tensile Strength - Thickness of S650MC High Yield Structural Steel Plate - S650MC Steel Plate Smallest Bending Radius - EN 10149-2 S650MC Sheet Dimensions - S650MC High Yield Structural Steel Plate Hot-rolled Slit Strip

650 High Yield Structural Coils Grade Standard And Specification

| Item | High Yield Structural 650 Plate |

| Standards | EN 10149-2, EN 10051, EN 10163-2 |

| Material | High Yield Structural 600 |

| Thickness | 2.00-10.00 milimeter |

| Width | up to 1600 milimeter |

| Length | Up to 16000 milimeter |

Check High Yield Structural 650 MC Plates Chemical Composition, 650MC Structural Steel Plates Mechanical properties, High Yield Structural Steel S650MC Plates Specification.

High Yield Structural 650 MC Plates Chemical Compatibility

| S | C | Al | Si1 | NB2 | Mn | V2 | P | Ti2 |

| 0.010 | 0.12 |

0.015 | 0.21 |

0.09 | 2.00 | 0.20 | 0.025 | 0.15 |

1) Sum of Nb, V and Ti = max 0.22%

650MC High Yield Structural Steel Sheets Mechanical Properties Analysis

Fastest Growing Supplier Of 650 Structural Steels Plate, S650 EN 10051 Steel Sheets Stockist In India, Get at discount of High Yield Structural S650MC Steel Plate, 650MC High Yield Structural Steel Sheets Distributor In India.

| Thickness (mm) | Elongation A 80 3) (min %) |

Yield strength R eH 1)2) (min MPa) |

Elongation A 5 (min %) |

Tensile strength Rm (MPa) | Min. inner bending radius for a 90° bend |

| 2.00- 3.00 | 12 | 650 | 14 4) | 700- 850 | 0.8 x t |

| 3.01- 6 | 650 | 14 | 700- 850 | 1.2 x t | |

| 6.01- 10 | 650 | 14 | 700- 850 | 1.5 x t |

Most Commonly Used S650MC High Yield Structural Steel Plate Types

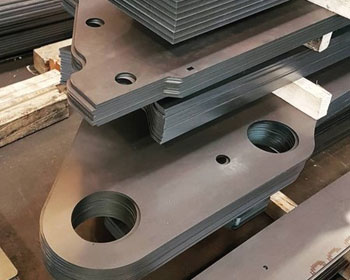

S650MC Grade D/E Plate

S650MC Grade D/E Plate

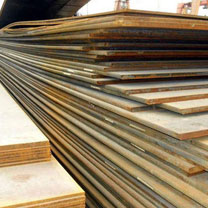

650 MPa Coils

650 MPa Coils

High Yield Structural Steel 650 MC Plates

High Yield Structural Steel 650 MC Plates

650MC Structural Steel Plates

650MC Structural Steel Plates

S650MC Plates

S650MC Plates

650 Structural Steel Plate

650 Structural Steel Plate

High Yield Structural S650MC Steel Plate

High Yield Structural S650MC Steel Plate

650MC Steel Sheets

650MC Steel Sheets

High Yield Structural 650 Sheets

High Yield Structural 650 Sheets

650 MC High Strength Steel Plates

650 MC High Strength Steel Plates

650MC EN 10149-2 Hot-Rolled Structural Steel Plate

650MC EN 10149-2 Hot-Rolled Structural Steel Plate

EN 10163-2 650 MC Hot-Rolled Heavy Plates

EN 10163-2 650 MC Hot-Rolled Heavy Plates

S650MC Grade D/E Plate

Refer High Yield Structural Steel 650 Sheets, S650MC Structural Steels Plate Properties, 650 MC High Strength Steel Plates Supplier In Bhopal, India, Stockist of 650MC EN 10149-2 Hot-Rolled Structural Steel Plate.

| USED | DIMENSIONS | STANDARDS |

|---|---|---|

| Structural | T: 2 - 10 milimeter W: Up to 1600 milimeter L: Up to 16000 milimeter |

EN 10149-2 EN 10051 EN 10163-2 |

Equivalent Material Of High Yield Structural Steel S650MC Plates

| Thickness(mm) | Typ CET(CEV) |

|---|---|

| 2.00 - 10.00 | 0.22 (0.34) |

650MC Structural Steel Plates Tolerances

Get a Live Quote Now For S650MC High Yield Structural Steel Plate, 650 MC Steel Plate, We provide EN 10163-2 650 MC Hot-Rolled Heavy Plates 3rd Party Testing And MPa 650 MC Plate Expert Cutting Service In Mum

- Thickness : High Yield Structural Steel Guarantees offer considerably narrower thickness tolerances compared to EN 10 051.

- Length and Width : The standard offer narrower width and length tolerances compared to EN 10 051

- Shape : Narrower tolerances according to the standard are available on request

- Flatness : High Yield Structural Steel flatness guarantees offer narrower tolerances compared to EN 10 051.

- Surface Properties : EN 10 163-2 Class A, Subclass 3

650 MPa Coils Plasma Cutting

| Cutting method | Kerf width | HAZ | Dim. tolerances |

|---|---|---|---|

| Plasma cutting | 2-6.5 mm | 2-5 mm | ± 1.0 mm |

S650MC Grade D/E Plate Laser Cutting

| Cutting method | Kerf width | HAZ | Dim. tolerances |

|---|---|---|---|

| Laser cutting | < 1 mm | 0.2-2 mm | ± 0.2 mm |

High Yield Structural 650 MC Plates Cutting Mathod

| Cutting method | Kerf width | HAZ | Dim. tolerances |

|---|---|---|---|

| Oxy-fuel cutting | 2-5 mm | 4-10 mm | ± 2.0 mm |

S650MC Steel Plate Typical Tensile Strength

| TYPE OF STEEL | TYPICAL TENSILE STRENGTH (MPa) |

|---|---|

| High Yield Structural 650 MC | 800 |

Thickness of S650MC High Yield Structural Steel Plate

| THICKNESS (t) (mm) | ALONG ROLLING DIRECTION MINIMUM Ri/t | DIE OPENING WIDTH (W) MINIMUM W/t | ||

|---|---|---|---|---|

| HOT ROLLED STRIP | High Yield Structural 650 MC | t ≤ 3 3 < t ≤ 6 t > 6 |

0.8 1.2 1.5 |

10 10 10 |

S650MC Steel Plate Smallest Bending Radius

| Nom. thick. e | smallest bending radius |

| ≤3 mm | 1.5 x e |

| 3 < e ≤ 6 mm | 2.0 x e |

| > 6 mm | 2.5 x e |

EN 10149-2 S650MC Sheet Dimensions

| Thickness in mm | Width in mm |

| 2.00 – 2.99 mm | 900 –1300 mm |

| 3.00 – 3.99 mm | 900 –1450 mm |

| 4.00 – 6.00 mm | 900 –1500 mm |

S650MC High Yield Structural Steel Plate Hot-rolled Slit Strip

| Thickness in mm | Width in mm |

| 2.50 – 2.99 mm | 100 – 640 mm |

| 3.00 – 4.60 mm | 100 – 690 mm |

| 4.61 – 6.00 mm | 140 – 740 mm |