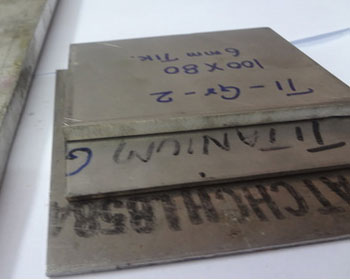

Get at discount of Titanium Grade 2 Plate, Cp3 Grade 2 Titanium Sheet.

Titanium Grade 2 Plate is made up of a titanium alloy that is used mostly in marine applications, chemical processing plants and in aerospace applications. Suryadeep Industry is a leading manufacturer and supplier of the Titanium Gr 2 Plates in various dimensions and types. There are different types, forms and finishes of the CP Gr 2 Titanium Plate products used in the different applications. The specification of this grade is ASTM B265. The material is standardized under ASTM, ASME and API standards. The Titanium Alloy Gr 2 Coils are one form of the plates and the plates range in dimensions. The thickness of the plates ranges from 4mm to 100mm with the size ranging from 0.187inches to 2 inches. The Ti. Alloy Gr 2 Sheets are made in different hardness scales. The soft, hard, half hard, quarter hard and spring hard variations are available in all forms such as the Titanium Gr 2 Circle and the coil.

The grading for the grade 2 titanium is the UNSR50400. The composition of the grade is carbon, nitrogen, oxygen, hydrogen, iron and titanium. Titanium is a naturally occurring strong and corrosion resistant material. so the Titanium UNS R50400 Plates are also strong and corrosion resistant to most applications. The material also has a high melting point at 1670 degrees Celsius. This makes the ASME SB265 Titanium Gr 2 Plate applicable in high heat applications as well. The thermal conductivity, modulus elasticity are good and the density is about half the density of most stainless steels. So the Titanium Gr 2 Slatting Coil and other applications have the advantage of light weight components. The minimum tensile strength is 40ksi and the minimum yield strength is 14.9ksi. The Gr 2 Titanium Hot Rolled Plates can operate under high temperatures with high strength and with high corrosion resistance properties, but the price of the material is costlier than most steel alloys. Please contact us for the Titanium Gr 2 Cold Rolled Plates information and the prices.

Table of Content - Titanium Grade 2 Sheet Sizes And Schedule Specifications - CP3 Gr 2 Titanium Plate Chemical Compatibility - Titanium Alloy Gr 2 Coils Mechanical Properties Database - Equivalent Grades Of Ti. Alloy Gr 2 Sheets - UNS R50400 Plates Physical Properties - List Of Titanium Grade 2 Plate Types - Titanium Gr.2 2d Plate Size chart - Titanium Gr.2 2d Plate Thicknesses - ASTM B265 Titanium Gr 2 Shim Sheets Weight Chart

Titanium Grade 2 Sheet Sizes And Schedule Specifications

| Specifications | ASTM / ASME SB265 |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Size | 1000 milimeter x 2000 milimeter, 1220 milimeter x 2440 milimeter, 1500 milimeter x 3000 milimeter, 2000 milimeter x 2000 milimeter, 2000 milimeter x 4000 milimeter |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Thickness | 0.1 milimeter to 12 milimeter Thk |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

Check Attractive Price Offer On CP3 Gr 2 Titanium Plate In India, Titanium Alloy Gr 2 Coils Specification, Ti. Alloy Gr 2 Sheets Size Chart.

CP3 Gr 2 Titanium Plate Chemical Compatibility

| Grade | N | Ti | Al | C | H | Fe | V | O |

| Ti Grade2 | 0.03 | 99.2 | – | 0.1 | 0.015 | 0.3 | – | 0.25 |

Titanium Alloy Gr 2 Coils Mechanical Properties Database

| Element | Yield Strength (0.2%Offset) | Density | Tensile Strength | Melting Point | Elongation |

| Titanium Gr. 2 | Psi – 39900 , MPa – 275 | 4.5 g/cm3 | Psi – 49900 , MPa – 344 | 1665 °C (3030 °F) | 20 % |

Equivalent Grades Of Ti. Alloy Gr 2 Sheets

Titanium Gr 2 Circle Stockists, Huge inventory of Titanium UNS R50400 Plates, ASME SB265 Titanium Gr 2 Plate Manufacturer In India, Check Equivalent Of Titanium Gr 2 Slatting Coil.

| STANDARD | UNS | WERKSTOFF NR. |

| Titanium Gr. 2 | R50400 | 3.7035 |

UNS R50400 Plates Physical Properties

| Modulus of Elasticity, ksi (MPa) | 15.2 x 10³(105 x 10³) in tension |

| Density | 0.163 lbs/in³ , 4.51 g/cm³ |

| Thermal Conductivity: BTU-in/h-ft-°F (W/m-°K) | At 70°F (21°C): 114(16.4) |

| Mean Coefficient of Thermal Expansion, in/in/°F (mm/m/°C) | 70- 212°F (20- 100°C): 4.78 x 10-6 (8.6) |

| Melting Point | 3040°F (1670°C) |

List Of Titanium Grade 2 Plate Types

Titanium Alloy Gr 2 Coils

Titanium Alloy Gr 2 Coils

Ti. Alloy Gr 2 Sheets

Ti. Alloy Gr 2 Sheets

Titanium Gr 2 Circle

Titanium Gr 2 Circle

Titanium UNS R50400 Plates

Titanium UNS R50400 Plates

ASME SB265 Titanium Gr 2 Plate

ASME SB265 Titanium Gr 2 Plate

Titanium Gr 2 Slatting Coil

Titanium Gr 2 Slatting Coil

Titanium Grade 2 Polish Plate

Titanium Grade 2 Polish Plate

Gr 2 Titanium Hot Rolled Plates

Gr 2 Titanium Hot Rolled Plates

Cp Grade 2 Titanium Sheet

Cp Grade 2 Titanium Sheet

Titanium Gr 2 Cold Rolled Plates

Titanium Gr 2 Cold Rolled Plates

Titanium Gr.2 2d Plate

Titanium Gr.2 2d Plate

Titanium Alloys Gr 2 Perforated Coil

Titanium Alloys Gr 2 Perforated Coil

Gr 2 Titanium Hot Rolled Plates Density

Titanium Grade 2 Polish Plate Stockist In India, Fastest Growing Supplier Of Gr 2 Titanium Hot Rolled Plates, Get at discount of Titanium Gr 2 Cold Rolled Plates, Titanium Gr.2 2d Plate Manufacturer In India.

| UNS R50400 Titanium Grade 2 Plate density |

| 0.1630 lb/in³ 4.512 g/cm3 |

Titanium Grade 2 Polish Plate Melting Range

| ASTM B265 Titanium Alloy Gr 2 Plate melting range |

| °F: 3020-3040 °C: 1660-1671 |

Titanium Gr.2 2d Plate Size chart

| Stocked Sizes | |

|---|---|

| Size (in inches) | Size (in milimeter) |

| .125" | 3.18 |

| .134" | 3.40 |

| .156" | 3.96 |

| .187" | 4.75 |

| .250" | 6.35 |

| .312" | 7.92 |

| .375" | 9.53 |

| .500" | 12.7 |

| .600" | 15.9 |

| .750" | 19.1 |

| .875" | 22.2 |

| 1" | 25.4 |

| 1.125" | 28.6 |

| 1.250" | 31.8 |

| 1.500" | 38.1 |

| 1.750" | 44.5 |

| 2" | 50.8 |

| 2.500" | 63.5 |

| 3" | 76.2 |

Werkstoff No 3.7035 Shim Sheet Imperial Dimensions

| Plate Surface finish | Width (max inches) | Gauge (inches) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed Plate | 72* | 10–24 |

| 2D – Cold rolled, heat treated, pickled plate | 60 | 12–24 |

| BA Mexinox only | 48 | 18–28 |

| Polished plate (not brushed) | 60 | 11–24 |

| Temper rolled plate Mexinox only | 48 | 13–29 |

Alloys Gr 2 Perforated Coil Metric Dimensions

Refer Titanium Alloys Gr 2 Perforated Coil Dimensions And Weight Chart, Looking to buy Titanium Grade 2 Plate? contact Suryadeep Industry, A Reliable Titanium Werkstoff No 3.7035 Shim Sheet Manufacturer in India

| Plate Surface finish | Width (max milimeter) | Thickness (milimeter) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed plate | 2032 | 0.25–8.0 |

| 2D – Cold rolled, heat treated, pickled plate | 1524 | 0.4–6.35 |

| 2E – Cold rolled, heat treated, mechanically descaled plate | 2032 | 0.4–8.0 |

| 2R – Cold rolled, bright annealed plate | 1524 | 0.25–3.5 |

| 2H – Work hardened plate | 1524 | 0.4–6.35 |

| Polished, brushed plate | 1524 | 0.5–4.0 |

Titanium Gr.2 2d Plate Thicknesses

| 0.5 mm 0.6 mm 0.8 mm 1.0 mm 1.2 mm 1.5 mm 1.6 mm 1.8 mm 2.0 mm 3.0 mm |

4.0 mm 5.0 mm 6.0 mm 8.0 mm 10.0 mm 12.0 mm 15.0 mm 20.0 mm 25.4 mm |

Gr 2 Titanium Plate Stock List

| Product form | Dimension |

|---|---|

| Plate; cold rolled | 0.4x1000x2000 mm, 3.45 kg/pc |

| Plate; cold rolled, annealed, clean | 0.5x1000x2000 mm, 4.51 kg/pc. |

| Plate; cold rolled | 0.6x995x2000 mm, 5.5 kg/pc |

| Plate; pickled, annealed | 1.0x1250x3000 mm, 16.9 kg/pc |

| Plate; | 1.5x1000x2000 mm, 13.54 kg/pc. |

| Plate; | 1.5x1000x2500 mm, 16.92 kg/pc. |

| Plate; annealed | 1.5x1000x3000 mm, 20 kg/pc |

| Plate; | 1.5x1000x3000 mm, 20.31 kg/pc. |

| Plate; | 1.54x1250x2000 mm, 17.37 kg/pc. |

| Plate; annealed | 2.0x1000x3000 mm, 27.2 kg/pc |

| Plate; annealed | 2.0x1500x3000 mm, 40.5 kg/pc |

| Plate; cold rolled | 2.5x1220x3000 mm, 42 kg/pc |

| Plate; annealed | 3.0x1000x3000 mm, 40.5 kg/pc |

| Plate; annealed | 3.0x1500x3000 mm, 60.75 kg/pc |

| Plate; annealed | 4.0x1000x3000 mm, 54 kg/pc |

| Plate; cold rolled | 4.0x1500x3000 mm, 81.0 kg/pc |

| Plate; annealed | 5.0x310x310 mm, 2,17 kg/pce. |

| plate | 5.0x1250x4000 mm, 112,75 kg/Stk. |

| Plate; annealed | 5.0x2000x3000 mm, 133 kg/pc |

| plate | 6.0x1250x4000 mm, 135,3 kg/Stk. |

| Plate; annealed | 6.0x2000x6000 mm, 349 kg/pc |

| Plate; annealed | 8.0x2000x6000 mm, 434 kg/pc |

| Platte | 8.0x1000x3000 mm, 108,24 kg/St. |

| plate | 8.0x1000x2000 mm, 72,16 kg/St. |

| Plate; annealed | 10x2000x3000 mm, 296 kg/pc |

| plate | 10.0x1250x4000 mm, 225,50 kg/Stk. |

| Plate; annealed | 12.0x2000x3000 mm, 352 kg/pc |

| Plate; annealed | 15.0x2000x3000 mm, 405 kg/pc |

| plate | 15.0x500x1000 mm, 33,83 kg/Stk. |

| Plate; annealed | 20.0x2000x3000 mm, 540 kg/pc |

| Plate; annealed | 25.0x2000x3000 mm, 675 kg/pc |

| Plate; annealed | 30.0x2000x3000 mm, 810 kg/pc |

| Plate; annealed | 40.0x2000x3000 mm, 1080 kg/pc |

| Plate; annealed | 50.0x2000x3000 mm, 1354 kg/pc |

| Plate; annealed | 50.0x2000x3000 mm, 1896 kg/pc |

ASTM B265 Titanium Gr 2 Shim Sheets Weight Chart

| Thickness(inches) | Density | Plate Weight per Unit Area |

|---|---|---|

| 3/16 | 0.315 lbs/in³8.72 g/cm³ | 0.06000 lbs/in²42.184176 kg/m² |

| 1/4 | 0.315 lbs/in³8.72 g/cm³ | 0.08 lbs/in²56.245568 kg/m² |

| 3/8 | 0.315 lbs/in³8.72 g/cm³ | 0.121 lbs/in²85.0714216 kg/m² |

| 1/2 | 0.315 lbs/in³8.72 g/cm³ | 0.161 lbs/in²113.1942056 kg/m² |

| 5/8 | 0.315 lbs/in³8.72 g/cm³ | 0.196 lbs/in²137.8016416 kg/m² |

| 3/4 | 0.315 lbs/in³8.72 g/cm³ | 0.235 lbs/in²165.221356 kg/m² |

| 7/8 | 0.315 lbs/in³8.72 g/cm³ | 0.274 lbs/in²192.6410704 kg/m² |

| 1 | 0.315 lbs/in³8.72 g/cm³ | 0.313 lbs/in²220.0607848 kg/m² |

| 1 1/4 | 0.315 lbs/in³8.72 g/cm³ | 0.391 lbs/in²274.9002136 kg/m² |

| 1 1/2 | 0.315 lbs/in³8.72 g/cm³ | 0.47 lbs/in²330.442712 kg/m² |

| 1 3/4 | 0.315 lbs/in³8.72 g/cm³ | 0.549 lbs/in²385.9852104 kg/m² |

| 2 | 0.315 lbs/in³8.72 g/cm³ | 0.627 lbs/in²440.8246392 kg/m² |

| 2 1/4 | 0.315 lbs/in³8.72 g/cm³ | 0.705 lbs/in²495.664068 kg/m² |

| 2 1/2 | 0.315 lbs/in³8.72 g/cm³ | 0.784 lbs/in²551.2065664 kg/m² |

| 2 3/4 | 0.315 lbs/in³8.72 g/cm³ | 0.862 lbs/in²606.0459952 kg/m² |

| 3 | 0.315 lbs/in³8.72 g/cm³ | 0.941 lbs/in²661.5884936 kg/m² |