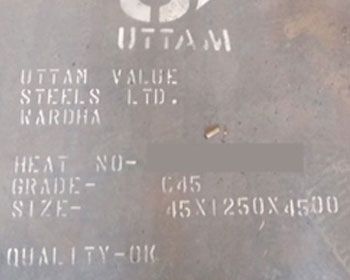

PED Certified C45 Plate, C45 Carbon Steel Sheets Supplier in Bhopal, India

C45 Steel Plate has moderate strength and is made up of a medium carbon steel. The material could be hardened by further heat treatments. Suryadeep Industry is one of the leading manufacturers and C45 Plate Suppliers. The material is usually distributed in untreated conditions but could be supplied in different variations according to customer requirements. The C45 Steel Plates are commonly used in gears, automotive components, general engineering and in other applications. The composition has nickel, chromium, molybdenum, silicon, manganese, copper, carbon, sulfur and phosphorus in it. The C45 Carbon Steel Sheets come in different widths ranging from 600mm to 2500mm and can be ordered to custom widths as well. The length of the plates range from 600mm to 12000mm and the thickness of the sheets and plates range from 0.2mm to 400mm.

The C45 Hot Rolled Plates can be modified with different levels of phosphorus and sulfur. The c45E has limited amounts of phosphorus and sulfur. The High Carbon Steel C45 S45C 1045 C-45 Plates can also come in enhanced machining properties. The c45R is the variation that comes with this enhancement by minimizing the phosphorus and sulfur levels. The Carbon Steel C45 Boiler Plates are high pressure capable and can operate under boiler temperatures. The material is heat treated to get the desired capacities. The C45 Sheets can be soft annealed, normalized, quenched and tempered or turned. The C45 Carbon Steel Circle can also be found in additional hardenability test and with enhanced hardenability test. The SC 45 CS Perforated Coils are also used in similar capacities but with less weight per surface area. Please contact us for more information on the Carbon Steel C45 Sheet and the pricing.

Table of Content - C45 Plate Sizes And Schedule Specifications - SC 45 CS Perforated Coils Chemical Composition Chart - Carbon Steel C45 Sheet Mechanical Properties Chart - Equivalent Of C-45 Plate - List Of C45 Steel Sheet Types - C45 Carbon Steel Sheets Tolerances - Grade C-45 Carbon Steel Plates Standard Length Tolerances - Application of C45 Steel Plates - Advantages of C45 Plates - C45 Carbon Steel Sheets Thickness

C45 Plate Sizes And Schedule Specifications

| HSN Code | 72083610 |

| Thickness | 2 - 600 milimeter |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Width |

4200 - 11000 milimeter |

| Wall Thickness | 0.2 - 400 milimeter |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR) |

| Surface | Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE |

| Length |

3000 - 18000 milimeter |

| Thickness | 0.2 ~ 300 milimeter |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip etc. |

SC 45 CS Perforated Coils Supplier In India, We provide Carbon Steel C45 Sheet with instant delivery, Specification Of C-45 Plate.

SC 45 CS Perforated Coils Chemical Composition Chart

| Grade | S | C | Cr | Mn | Si | P |

|---|---|---|---|---|---|---|

| C45 Sheets | 0.025 max | 0.42-0.50 | 0.20-0.40 | 0.50-0.80 | 0.15-0.35 | 0.025 max |

Carbon Steel C45 Sheet Mechanical Properties Chart

Chemical And Mechanical Composition Of C45 Hot Rolled Plates, C45 Carbon Steel Plate Stockist In India, Check Our Global Sales Network For C45 Steel Grade Plates.

| Grade | Elongation |

Condition | Hardness HRC |

Yield Strength |

Quenching Temperature |

Tensile Strength |

Benda- bility |

Nominal Thickness,t 1.95mm≤t≤10.0mm |

|

|---|---|---|---|---|---|---|---|---|---|

| Annealed | Rolled | ||||||||

| C45 Sheets | 18 30 |

Rolled Annealed Water-quenched Oil quenched |

58 55 |

460 330 |

820 860 |

750 540 2270 1980 |

Min.reco-mmended Bending radius (≤90°) |

1.0×t | 2.0 ×t |

Equivalent Of C-45 Plate

| STANDARD | SAE | DIN 17200 | JIS G 4051 | BS | Steel Number | AFNOR |

|---|---|---|---|---|---|---|

| En 19 | C45 | C 45 | S 45 C | C45, AF65C45, 1C45 | 1.0503 | 1045 |

List Of C45 Steel Sheet Types

Carbon Steel C45 Steel Plate Stockist In India, Fastest Growing Supplier Of EN 10083 C45 Plate, Get at discount of Carbon Steel C45 Boiler Plates, C45 Sheets Manufacturer In India.

C45 Plate

C45 Plate

SC 45 CS Perforated Coils

SC 45 CS Perforated Coils

Carbon Steel C45 Sheet

Carbon Steel C45 Sheet

C-45 Plate

C-45 Plate

C45 Carbon Steel Sheets

C45 Carbon Steel Sheets

C45 Hot Rolled Plates

C45 Hot Rolled Plates

C45 Carbon Steel Plate

C45 Carbon Steel Plate

C45 Steel Grade Plates

C45 Steel Grade Plates

Carbon Steel C45 Steel Plate

Carbon Steel C45 Steel Plate

EN 10083 C45 Plate

EN 10083 C45 Plate

Carbon Steel C45 Boiler Plates

Carbon Steel C45 Boiler Plates

C45 Sheets

C45 Sheets

C45 Carbon Steel Sheets Tolerances

Buy C45 Carbon Steel Circle Best Price & C45 Steel Plate Fast Delivery, Manufacturer Of C45 Steel Sheet, Carbon Steel C45 HR Plate, Grade C-45 Carbon Steel Plates In India.

| Execution | OD Tolerance | Size Range | Wall tolerance |

|---|---|---|---|

| Hot-rolled Tube | ± 0.4 mm± 0.5 % of OD | OD – 80 mmOD > 80 mmWall | ± 0.7 mm± (5 % x wallthickness + 0.1 mm |

| Hot-rolled peeled tube | + 0.25/- 0 mm | All sizesWall | ± 0.8 mm± (5 % x wall thickness+ 0.2 mm) |

| Cold Worked tubecold-rolled or cold-drawn | + 0.30/- 0 mm*+ 0.35/- 0 mm*+ 0.40/- 0 mm* | OD 80 Wall Thickness 8 | ± 0.30 mm± 0.35 mm± 0.40 mm |

Straightness : The maximum deviation from the straight line is 1 mm on a gauge length of 1000 mm.

Ovality : The maximum out-of-roundness of C45 Sheets is 65% of the total outer diameter tolerance.

Grade C-45 Carbon Steel Plates Standard Length Tolerances

| C45 Sheets Component length (milimeter) | OD 100-254 (milimeter) | OD 30-100 (milimeter) |

|---|---|---|

| 10-100 | + 2.0/- 0 | + 1.0/- 0 |

| 100-600 | + 3.0/- 0 | + 2.0/- 0 |

| 600-1200 | + 4.0/- 0 | + 3.0/- 0 |

| 1200-5000 | + 6.0/- 0 | + 5.0/- 0 |

Application of C45 Steel Plates

- Ship building

- Structural application in freight cars

- Transmission towers

- Dump trucks

- Crane

- Trailers

- Construction

- Mechanical manufacturing

- Oil and gas platforms

- Power plant

- Palm oil equipment’s and machineries

Advantages of C45 Plates

- Robust construction

- Resistance to atmospheric corrosion

- High ductility

C45 Carbon Steel Sheets Thickness

| Heavy plates Thickness mm | Upper tolerance mm | Sheets Thickness mm | Upper tolerance, width-wise mm | |

|---|---|---|---|---|

| -1200 | 1201 – 1500 | |||

| 6.00 – 6.99 | 0.74 | 2.50 – 3.00 | 0.30 | 0.32 |

| 7.00 – 7.99 | 0.76 | 3.01 – 4.00 | 0.32 | 0.36 |

| 8.00 – 9.99 | 0.80 | 4.01 – 5.00 | 0.36 | 0.40 |

| 10.00 – 11.99 | 0.90 | 5.01 – 6.00 | 0.40 | 0.42 |

| 12.00 – 14.99 | 1.00 | 6.01 – 6.50 | 0.44 | 0.44 |

| 15.00 – 19.99 | 1.10 | |||

| 20.00 – 24.99 | 1.20 | |||

| 25.00 – 29.99 | 1.30 | |||

| 30.00 | 1.40 | |||