-

Email ID: [email protected]

-

Call Us:

Email ID: [email protected]

Call Us:

Stainless Steel ERW Pipe is an Electric Resistance Welded Pipe. ERW steel pipes & tubes are used in many industrial applications. ASTM A213 304 ERW Pipes & tubes are used in various engineering purposes, scaffolding, fencing, line pipes, etc. ERW steel pipes are available in various qualities, wall thicknesses, and diameters of the finished pipes. SS 304 Electric Resistance Welded Pipes replace its usage for Agricultural purposes, Drinking Water for housings, in collieries for extraction of Water, Transports, Thermal Powers, Hand pumps for deep boring wells, as strong protection for cables by Telecom Department, Structural Purposes and so on.

Stainless Steel ERW Tubes

SS 316 ERW Pipe

Welded stainless steel pipe

| Stainless Steel 304 Electric Resistance Welded Pipe Specification | ||

|---|---|---|

| Material Grade | Stainless Steel 304 | |

| Standard | ASTM A - 270, 249, 312, 269, 213, 268, 358, ASTM A106 | |

| Dimensions | ASTM,ASME,API | |

| Size | 8" NB to 24" NB | |

| Schedules | SCH 5S , 10S ,10, 20 , 40S , 40 , STD , 60 , 80S , 80 , XS , 100 , 120 , 140 , 160 & XXS | |

| Type | Electric Resistance Welded | |

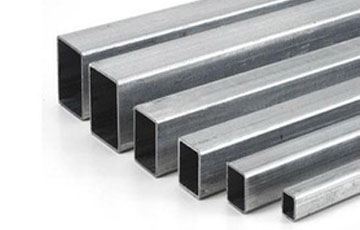

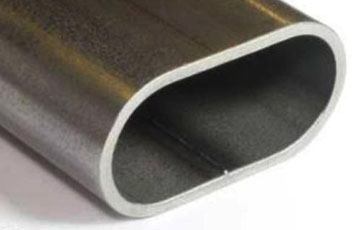

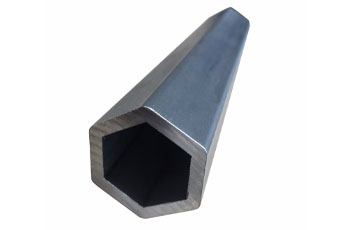

| Form | Round, Square, Rectangular, Hydraulic Pipes | |

| Wall Thickness | 0.5 to 150mm Thick | |

| Accurate Engineering Indutsries Specialized in | Large Diameter Size | |

| End | Plain End, Beveled End, Treaded | |

| Length | Single Random, Double Random & Cut Length. | |

| Materials Testing | NACE MR0175, H2 SERVICE, OXYGEN SERVICE, CRYO SERVICE, etc | |

| Processing | Cut-to-length, polishing,Polished Grit 120 - 600 | |

While manufacturing SS DIN 1.4301 ERW Rectangular Pipes only high-quality, control-rolled, fully killed, fine-grain, continuous-cast, low-carbon steel is used. High-performance pipes & tubing possess high strength corrosion resistance, high deformability, high strength, and high toughness. We are the leading stockholders and suppliers of ERW pipes &tubes in India. We are also one of the largest Stainless Steel 304 ERW Pipe and 304 SS ERW Hydraulic Pipes Exporter Leading Manufacturers in India.

Depending on the customer’s requirements we can manufacture ERW pipes and tubes of different shape and size. We have a very large production capacity of ASTM A312 TP 304 SS ERW Pipes and are used in various engineering purposes, scaffolding, fencing, line pipes, etc. These pipes are available in lengths from single random to 120 feet depending on mill capability. They are available with square ends or beveled for threaded, welding and coupled and Victaulic grooved. The surface finishes are available in black or bare, or with protective coatings.

We offer a huge array of ASTM A249 JIS SUS 304 ERW Pipes that are fabricated by using various grades of material steel and metal alloys. They are single welded or double welded. SS ERW pipes are fabricated in different alloys. We offer pipes with radiography or without radiography. Our comprehensive range includes UNS S30400 ERW Square Pipes, ERW alloy steel pipes, welded steel pipes and many more. We produce using world-class quality of steel and alloy to retain their durability for a longer period.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| NB SIZES | SCH 5 | SCH 10 | SCH 40 | SCH 80 | SCH 160 |

|---|---|---|---|---|---|

1/8″ |

|||||

1/4″ |

|||||

3/8″ |

|||||

1/2″ |

|||||

3/4″ |

|||||

1″ |

|||||

1 1/4″ |

|||||

1 1/2″ |

|||||

2″ |

|||||

2 1/2″ |

|||||

3″ |

|||||

4″ |

|||||

5″ |

|||||

6″ |

| Pressure Rating (psig) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Size (inches) |

Schedule | Temperature (oF) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1" | 40 | 3048 | 2629 | 2362 | 2171 | 2019 | 1924 | 1867 | 1824 | 1810 |

| 80 | 4213 | 3634 | 3265 | 3002 | 2791 | 2659 | 2580 | 2528 | 2501 | |

| 160 | 6140 | 5296 | 4759 | 4375 | 4068 | 3876 | 3761 | 3684 | 3646 | |

| 1 1/2" | 40 | 2257 | 1947 | 1750 | 1608 | 1496 | 1425 | 1383 | 1354 | 1340 |

| 80 | 3182 | 2744 | 2466 | 2267 | 2108 | 2009 | 1949 | 1909 | 1889 | |

| 160 | 4619 | 3984 | 3580 | 3291 | 3060 | 2916 | 2829 | 2772 | 2743 | |

| 2" | 40 | 1902 | 1640 | 1474 | 1355 | 1260 | 1201 | 1165 | 1141 | 1129 |

| 80 | 2747 | 2369 | 2129 | 1957 | 1820 | 1734 | 1682 | 1648 | 1631 | |

| 160 | 4499 | 3880 | 3486 | 3205 | 2980 | 2840 | 2755 | 2699 | 2671 | |

| 3" | 40 | 1806 | 1558 | 1400 | 1287 | 1196 | 1140 | 1106 | 1084 | 1072 |

| 80 | 2553 | 2202 | 1979 | 1819 | 1691 | 1612 | 1564 | 1532 | 1516 | |

| 160 | 3840 | 3312 | 2976 | 2736 | 2544 | 2424 | 2352 | 2304 | 2280 | |

| 4" | 40 | 1531 | 1321 | 1187 | 1091 | 1014 | 967 | 938 | 919 | 909 |

| 80 | 2213 | 1909 | 1715 | 1577 | 1466 | 1397 | 1355 | 1328 | 1314 | |

| 160 | 3601 | 3106 | 2791 | 2566 | 2386 | 2273 | 2206 | 2161 | 2138 | |

| 5" | 40 | 1342 | 1158 | 1040 | 956 | 889 | 847 | 822 | 805 | 797 |

| 80 | 1981 | 1709 | 1535 | 1411 | 1312 | 1250 | 1213 | 1189 | 1176 | |

| 160 | 3414 | 2945 | 2646 | 2433 | 2262 | 2155 | 2091 | 2049 | 2027 | |

| 6" | 40 | 1219 | 1052 | 945 | 869 | 808 | 770 | 747 | 732 | 724 |

| 80 | 1913 | 1650 | 1483 | 1363 | 1267 | 1208 | 1172 | 1148 | 1136 | |

| 160 | 3289 | 2836 | 2549 | 2343 | 2179 | 2076 | 2014 | 1973 | 1953 | |

| 8" | 40 | 1073 | 926 | 832 | 765 | 711 | 678 | 657 | 644 | 637 |

| 80 | 1692 | 1459 | 1311 | 1205 | 1121 | 1068 | 1036 | 1015 | 1005 | |

| 160 | 3175 | 2738 | 2460 | 2262 | 2103 | 2004 | 1944 | 1905 | 1885 | |

| 10" | 40 | 974 | 840 | 755 | 694 | 645 | 615 | 596 | 584 | 578 |

| 80 | 1609 | 1388 | 1247 | 1147 | 1066 | 1016 | 986 | 966 | 956 | |

| 160 | 3147 | 2714 | 2439 | 2242 | 2085 | 1986 | 1927 | 1880 | 1868 | |

The below table shows the chemical composition of the used for Stainless Steel Pipes:

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

|

304 |

min. max. |

- 0.08 |

- 2.0 |

- 0.75 |

- 0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 10.5 |

- 0.10 |

|

304L |

min. max. |

- 0.030 |

- 2.0 |

- 0.75 |

- 0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 12.0 |

- 0.10 |

|

304H |

min. max. |

0.04 0.10 |

- 2.0 |

- 0.75 |

-0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 10.5 |

- |

| Element | SS 304 |

| Density | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Elongation | 35 % |

|

Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (μm/m/°C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Electrical Resistivity (nΩ.m) |

|||

|

0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

|||||

|

304/L/H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

Click below button to check full information of Stainless Steel ERW Pipe Price.

These Stainless Steel ERW Pipe are sold to a wide range of industries/markets, due to their overall corrosion resistance and good machinability: