Buy Ultra High Strength Steel 700MH Tubes, 700MLH High Yield Steel Tube At Low Price

High Strength Steel Tubing is a special type of tube that is used for high abrasion resistance, strength and hardness. The material is a brand known as domex that is rebranded. Suryadeep Industry is a leading supplier of the High Strength Steel 700MH Tubes which are the most used of the strenx tubes. There are different grades of strenx such as the 600MC, 700, 900 and so on. The material is strong and has 700MPa minimum yield strength. The 700MLH Tube has a high tensile strength ranging from 750MPa to 950MPa. It is a hot rolled plate material that is suitable for cold working and machining. The material has high forming capacity. The High Strength Circular Steel Tubes are used in high abrasion applications with high strength such as in construction material transportation like the wet concrete mixtures.

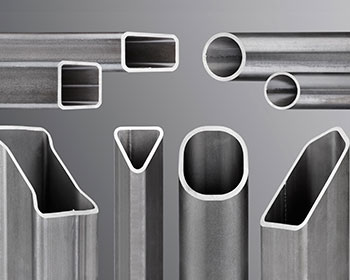

The High Strength Square Tube is used for its geometrical strength. The tubes come from 3mm to 10mm in wall thickness and the diameter can range from 30mm to 300mm. The High Strength Rectangular Tube mill length ranges from 6000 to 12000mm or sometimes up to 18000mm. The tubes can come in circular, square and rectangular shapes. The 700 MH High Strength Steel Tube is used in heavy load bearing applications and in high power machineries that deal with high friction applications. The petroleum refineries, oil and gas industrial applications, petrochemicals and pulp and paper industries all use the 700 MLH High Strength Structural Hollow Tubes for long lasting life. The 700 QLH Tubes have titanium, vanadium, niobium, aluminum and carbon in the composition which allows them to be stronger and abrasion resistant. The heat treatment makes the material even stronger. There are different types of these tubes such as the Steel 900 MH Tube and others. We manufacture and supply them according to international standards. Please contact us for any needs in the EN 1090-2 High Strength Steel Tubes.

Table of Content - High Strength Steel Tubing Dimensions Standard And Specification - 700MLH High Strength Steel Tube Chemical Properties - Ultra High Strength Steel Tubing Mechanical Strength - Basic Types Of High Yield Steel Tube - High Strength 900MH Steel Round Tube Tolerance

High Strength Steel Tubing Dimensions Standard And Specification

| Item | High Strength Steel Tube |

| High Strength Square Tube | 30x30 - 300x300 milimeter |

| Material | High Strength Steel Tubing - 700MH, 700MLH, 700QLH, 900MH, 960MH, 100XF |

| Standards | EN 10219-2, EN 1090-2 |

| Types | Circular, Square and Rectangular Shapes |

| Wall Thickness | 2.0 - 10.0 milimeter |

| High Strength Circular Tube | 33.7 - 323.9 milimeter |

| High Yield Rectangular Tube | 50x30 - 400x200 milimeter |

| Mill Length | 6000 - 12 000/18 000 milimeter |

Manufacturer Of High Strength Tubular Steel, Ultra High Strength Steel Tubing, Specifications Of 700MLH High Strength Steel Tube, Check the Market price before you buy High Strength Steel 900 MH Tube In India.

S700MLH High Strength Steel Tube Chemical Properties

| P | C | S | Si | Al tot | Mn | V | Nb | Ti |

| 0.020 | 0.12 | 0.012 | 0.25 | 0.015 | 2.10 | 0.20 1) | 0.090 1) | 0.15 1) |

Ultra High Strength Steel Tubing Mechanical Strength

Check High Strength 900MH Steel Round Tube Chemical Composition And Mechanical Properties Of Steel 100XF Circular Tubes, Ultra High Strength Steel Tubing, High Strength Steel Tubing.

| Yield Strength Rp0.2 | Elongatioal | Tensile Strength | Charpy-V -20°C 10x10 mm test specimen 1) (min J) |

| 700 | 10 | 750-950 | 40 |

Basic Types Of High Yield Steel Tube

Buy 700 MLH High Strength Structural Hollow Tubes Certified & Tested Materials, We provide Multiple Payment Options Of 700 QLH High Strength Steel Tubes, Properties Of EN 1090-2 High Strength Steel Tubes.

| High Strength Steel Tubing | Ultra High Strength Steel Tubing |

| High Strength Tubular Steel | Ultra High Strength Steel Tubing |

| High Strength Round Steel Tubing | High Yield Steel Tube |

| High Strength Low Alloy Steel Tubing | High Strength Steel 700MH Tubes |

| 700MLH High Strength Steel Tube | High Strength Circular Steel Tubes |

| High Strength Square Tube | High Strength Rectangular Tube |

| 700 MH High Strength Steel Tube | 700 MLH High Strength Structural Hollow Tubes |

| 700 QLH High Strength Steel Tubes | High Strength Steel 900 MH Tube |

| EN 1090-2 High Strength Steel Tubes | EN 1090-2 High Strength Steel Tubes |

| High Strength 900MH Steel Round Tube | Steel 100XF Circular Tubes |

High Strength 900MH Steel Round Tube Tolerance

We provide High Strength Circular Steel Tubes Expert Service In Bhopal, Get High Yield Steel Tube At Best Price, India, Get a Live Quote Now For High Strength Steel 700MH Tubes.

| Characteristic | Circular hollow sections Tolerances meet or exceed the requirements of EN 10219 |

| Thickness (T) | When D ≤ 323.9 mm: -5%/+10%, with a minimum of ±0.2 mm and maximum ±0.5 mm When 355.6 ≤ D ≤ 406.4 mm3): ±10%, when T ≤ 5 mm / ±0.5 mm, when T > 5 mm When D > 406.4 mm3): ±10%, with a maximum of ±2 mm |

| OD (D) 1) | ±1%, however a minimum of ±0.5 mm and a maximum of ±10 mm |

| Mass per unit length | Individual tube: ±6% |

| Out-of-roundness | 2%, when D/T ≤ 100 |

| Mill length | 0/+50 mm, 6000 ≤ L ≤ 12000 - 18000 mm (standard lengths 6000 & 12000 mm) |

| Straightness | 0.20% of total length and 3 mm over any 1 m length |

| Exact length | Agreed at the time of enquiry and order |