Alloy Steel AISI 4130 High Pressure Manifold Fittings, Also stock AISI 4130 Pipe Fittings & Flanges.

AISI 4130 High Pressure Manifold Fittings suppliers and manufacturer in India, buy any quantity & size at best price

Contents-

1. AISI 4130 High Pressure Manifold Fittings Specification

2. AISI 4130 High Pressure Manifold Fittings Packaging & Shipping

3. AISI 4130 other Alloy Steel Pipe & Fittings

4. AISI 4130 High Pressure Manifold Fittings Useful info

5. AISI 4130 Stock & AISI 4130 High Pressure Manifold Fittings Price

Get QUICK QUOTE now (best price guaranteed)

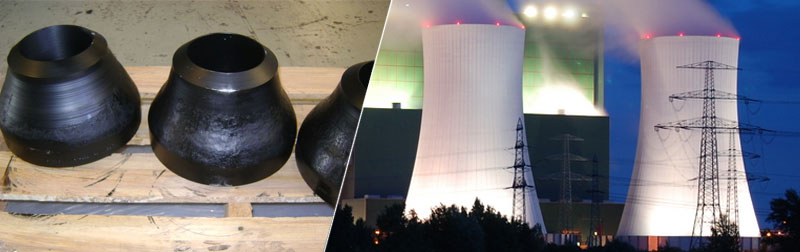

Do you need AISI 4130 High Pressure Manifold Fittings, API and ANSI pipe fittings, or fittings that meet any other standard for your next project? Then get in touch. We have a large selection of AISI 4130 High Pressure Manifold Fittings & Alloy Steel AISI 4130 Fittings to meet your needs. Plus, we can ship globally with a fast turn-around time.

When you buy AISI 4130 High Pressure Manifold Fittings, you want to be confident that it will perform as you expect. That’s why standardization systems are so important. They let us know that what we’re getting is what we think we’re getting, and that it won’t let us down. This is especially crucial when the consequences of a product failing are dire–like in an engineering project. The piping industry relies on standards. The AISI 4130 High Pressure Manifold Fittings are manufactured to sustain very high pressure and product warranty.

AISI 4130 High Pressure Manifold Fittings Specification

We accept all small/large quantity orders.

Description of AISI 4130 High Pressure Manifold Fittings

- Type: AISI 4130 High Pressure Manifold Fittings

Full ranges of fittings from 2″ to 6″ are available with standard pressure ratings of 5,000 psi and 10,000 psi.

- Service Class: Standard / Sour Service

- C.W.P. : 7,500 / 10,000 PSI

- Test Pressure: 11,250 /15,000 PSI

- Material: AISI 4130

- Weld Ends: ANSI B16.25

- BW Tolerances: ANSI B16.9

- Material Yield Strength: 85,000 PSI

- Material Tensile Strength: 105,000 PSI

AISI 4130 High Pressure Manifold Fittings Dimension

Full Flow High Pressure Manifold Fittings are manufactured from wrought iron steel. Crosses and Tees are closed die forges to ensure they have a correct grain flow, high integrity and uniform shape. Both 45° and 90° elbows are produced from hollow or tubular bars, hot formed on purpose made bending machines or forged in closed dies. Full ranges of fittings from 2″ to 6″ are available with standard pressure ratings of 5,000 psi and 10,000 psi.

Long Radius Elbows & Fittings

MD Exports LLP elbows have been forged and not welded to ensure that the end user obtains maximum results from the equipment. The following features of MD Exports LLP fittings enable them to be categorised in the highest standard of high-pressure equipment.

AISI 4130 High Pressure Manifold Fittings features:

- Eliminates post weld heat treatment requirements that restrict the material’s potential strength.

- Have smooth round uninterrupted bores to minimise pressure drop and turbulence.

- Inherently stronger.

- End fittings machined integrally.

- Do not require costly weld inspection.

- AISI 4130 High Pressure Manifold Fittings with fully pressure tested and certified.

- Full material tractability.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High Pressure Manifold Fittings

AISI 4130 Manifold Fittings are available either Full Flow or with reducing configurations in all pipe wall schedules, for the following pressure ratings:

| Max Working Pressure | 5,000 PSI | 7,500 PSI | 10,000 PSI | 15,000 PSI |

|---|---|---|---|---|

| Test Pressure | 7,500 | 11,250 | 15,000 | 22,500 |

| Operating Temperature Range | -60 to +345 Deg C | -60 to +345 Deg C | -60 to +345 Deg C | -60 to +345 Deg C |

| Min. Yield | 52,000 PSI | >80,000 PSI | >80,000 PSI | >80,000 PSI |

| Min. Tensile | 66,000 PSI | 105,000 PSI | 105,000 PSI | 105,000 PSI |

| Material | MSS-SP-75 Gr WPHY 52 | ASTM A234 Gr 4130 | ASTM A234 Gr 4130 | ASTM A234 Gr 4130 |

Wrought Steel Fittings

Buttwelding Fittings are available in either equal or with reducing configurations to suit various pressure ratings using materials as shown in the table below:

| Property | A234 Gr WPB | A420 Gr WPL6 | A182 Gr 316L | A860 Gr WPHY52 | A182 F51 31803 | UNS AISI 4130 |

|---|---|---|---|---|---|---|

| Tensile Strength | 60,000 PSI | 60,000 PSI | 70,000 PSI | 66,000 PSI | 90,000 PSI | 105,000 PSI |

| 415 MPa | 415 MPa | 485 MPa | 455 MPa | 620 MPa | 725 MPa | |

| Yield Strength | 35,000 PSI | 35,000 PSI | 25,000 PSI | 52,000 PSI | 65,000 PSI | >80,000 PSI |

| 240 MPa | 240 MPa | 170 MPa | 360 MPa | 450 MPa | >551 MPa | |

| Impact Values Deg C | N/A | 18J min.av. | N/A | 27J min.av. | 27J min.av. | 42J min.av. |

| -45 | -50 | -50 | -50 | |||

| Hardness (Max) | 197 HB | N/A | N/A | 235 HB | 237 HB | 237 HB |

| Elongation In 2” or 50mm | Long: 30% | Long: 30% | 30% | 32% | 25% | 18% |

| Trans: 20% | Trans: 16% |

The Right Industrial AISI 4130 High Pressure Manifold Fittings for Your Project!

We manufacture AISI 4130 High Pressure Manifold Fittings which are mainly used for high pressure Applications like sour services, Low temperature, onshore offshore Drilling, Manifold Equipments and Rig Projects.

Click on below for AISI 4130 High Pressure Manifold Fittings Specification:

- Alloy Steel AISI 4130 Fittings

- API Connections

- AISI 4130 High Pressure Manifold Fittings

- AISI 4130 Elbow

- AISI 4130 90° Long Radius Elbow

- AISI 4130 90° Short Radius Elbow

- AISI 4130 45° Long Radius Elbow

- AISI 4130 45° Short Radius Elbow

- AISI 4130 180° Long Radius Elbow

- AISI 4130 180° Short Radius Elbow

- AISI 4130 1D Elbow

- AISI 4130 1.5D Elbow

- AISI 4130 3D Elbow

- AISI 4130 5D Elbow

- AISI 4130 Seamless Buttwelding 45° and 90° Elbows

- AISI 4130 Alloy Steel Welded Elbows

- AISI 4130 Seamless Buttwelding 180° Returns

- AISI 4130 Straight Tees and Crosses

- AISI 4130 Reducing Outlet Tees and Reducing Outlet Crosses

- AISI 4130 Equal Tee

- AISI 4130 Reducing Tee

- AISI 4130 Equal Cross

- AISI 4130 Reducing Cross

- AISI 4130 Reducers

- AISI 4130 Concentric Reducer

- AISI 4130 Eccentric Reducer

- AISI 4130 Stub End

- AISI 4130 Lap Joint Stub Ends

- AISI 4130 Long Stubend

- AISI 4130 Short Stubend

- AISI 4130 Pipe Cap

- AISI 4130 End Cap

- AISI 4130 Collar

- AISI 4130 Swedge Nipple

- AISI 4130 Pipe Nipples

- AISI 4130 Barrel Nipple

- AISI 4130 Reducing Nipple

- AISI 4130 Alloy Steel Bend

- AISI 4130 Long Radius Bend

- AISI 4130 Piggable Bend

- AISI 4130 Lateral

- AISI 4130 Outlets

- HIGH PRESSURE AISI 4130 FITTINGS Specification:

- AISI 4130 Concentric Reducer

- AISI 4130 Eccentric Reducer

- AISI 4130 Double Back 90 Deg Elbow

- AISI 4130 Double Back 45 Deg Elbow

- AISI 4130 Cross

- AISI 4130 API 6A 10K RTJ Weld Neck Flange

- AISI 4130 API 6A 15K RTJ Weld Neck Flange

- AISI 4130 Long Radius 90 Deg Elbow

- AISI 4130 Long Radius 45 Deg Elbow

- AISI 4130 ANSI B16.9 Equal Tee

- AISI 4130 Equal Tee

CONTACT US FOR A QUICK QUOTE

Get AISI 4130 High Pressure Manifold Fittings price list, send an email to us at [email protected],AISI 4130 High Pressure Manifold Fittings quality certificates

AISI 4130 High Pressure Manifold Fittings & all Alloy Steel pipe fittings delivered with a NACE 3.1 Certification, Mill Test Certification and ISO 17025 Standards by a Government of India approved Laboratory.

AISI 4130 High Pressure Manifold Fittings Packaging & Shipping

AISI 4130 High Pressure Manifold Fittings Packing: We focus on every procedure to assure quality, the package we usually take is pack AISI 4130 High Pressure Manifold Fittings with environmental poly bags, and then in free fumigation wooden cases or wooden palte. Also can accept customized package such as OEM by negotiation.

MD Exports LLP offers just about everything to meet your Fittings pack requirements. Lot of emphasis is placed on the packing and packaging . The AISI 4130 High Pressure Manifold Fittings are packed in wooden corrugated boxes foiled in plastic wraps and bubble wraps. Caps are made available to the ends on request of the buyer.

AISI 4130 High Pressure Manifold Fittings Marking: All alloy stel fittings are marked with size, cast number and specification. Or as per customer’s requirement;

Packing Type for Alloy Steel AISI 4130 Tee, Elbow, Cross, Reducers etc.

AISI 4130 High Pressure Manifold Fittings Inner packing

AISI 4130 High Pressure Manifold Fittings Outer packing

So, besides the fact that we can arrange freight transportation for you, we can before that:

- specifically mark parts or packages;

- provide for a special packing according to what is required by the shipping method or by you.

We mark the AISI 4130 High Pressure Manifold Fittings as needed with the most suitable marking technique.

When packaging and packing, our experienced warehouse staff systematically takes the greatest precautions for your AISI 4130 High Pressure Manifold Fittings to be optimally protected during transportation. We pack the AISI 4130 High Pressure Manifold Fittings according to the appropriate method: strapped pallet, wooden crate, overseas packing (ISPM15).

>AISI 4130 other Alloy Steel Pipe & Fittings

- AISI 4130 Alloy Steel Pipes

- AISI 4130 Alloy Steel SEAMLESS Pipes

- ASTM A519 4130 Alloy Steel Pipes

- ASTM A519 4130 Alloy Steel SEAMLESS Pipes

- AISI 4130 75K Alloy Steel SEAMLESS Pipes

- AISI 4130 Alloy Steel DRILLING Pipes

- 4130 Alloy Steel Tubes

- AISI 4130 Alloy Steel Tubes

- AISI 4130 Alloy Steel SEAMLESS Tubes

- AISI 4130 L 80 Alloy Steel SEAMLESS Tubes

- A519 4130 Seamless Alloy Steel Tube

- 4130 Alloy Steel Tubing

- Chrome Moly Tubing 4130

- 4130 ALLOY STEEL ROUND SEAMLESS TUBING

- Alloy Steel 4130 Round Tubing

- 4130 Aircraft Tubing

- 4130 Alloy Steel seamless tubing

- 4130 Alloy Steel Rectangular Tubing

- ASTM A519 4130 Alloy Steel Mechanical Tubing

- AISI 4130 Alloy Steel Flanges

- Alloy Steel AISI 4130 Fittings

- AISI 4130 API Flanges

- AISI 4130 Alloy Steel Outlets

AISI 4130 High Pressure Manifold Fittings Useful info

AISI 4130 Alloy Steel (UNS G41300)

Integrating fittings into piping systems is a various important task. After all, it’s at the connections between pipes where the system is most susceptible to leaks and failure. As such, many pipe fitting connection methods require special training to be executed. From soldering, to threading to brazing, there are many types of connection methods. One of the most popular, however, is welding. To give you a brief idea of how it works, let’s look at how standards apply to industrial pipe fittings. AISI 4130 High Pressure Manifold Fittings standards give us information about how fittings were designed, how they were constructed, and how they can be expected to perform. Some of the characteristics that pipe fitting standards cover include:

- Size

- Pressure-temperature ratings

- Design

- Materials

- Coatings

- Marking

- Threading

- End connections

- Dimensions and tolerances

- Pattern taper

Types Of Industrial Pipe Fitting Standards

There are a number of organizations that specify pipe fitting standards. Some of the most well-known include:

- ANSI: The American National Standards Institute

This private, non-profit organization coordinates the U.S. voluntary standardization and conformity assessment system. ANSI’s ‘schedule numbers’ classify wall thicknesses for different pressures uses.

- ASME: American Society For Mechanical Engineers

ASME is one of the most respected organizations when it comes to developing standards and codes.

- ASTM International: American Society for Testing And Materials

One of the largest voluntary standards development organizations, ASTM develops and publishes voluntary standards on the basis of materials, products, systems and services. Its standards include pipes, tubes and fittings.

Specifications

| Standard | Alloy Steel |

|---|---|

| AISI 4130 Alloy Steel | UNS G41300 |

| AISI 4340 Alloy Steel | UNS G43400 |

| AISI 4140 Alloy Steel | UNS G41400 |

| AISI 8620 Alloy Steel | UNS G86200 |

Alloy Steel Chemical Composition

|

Chemical Composition Ranges and Limits, percent |

||||||||

| AISI Number |

C |

Mn |

P Max. |

S Max. |

Si |

Ni |

Cr |

Mo |

|---|---|---|---|---|---|---|---|---|

| AISI 4130 | 0.28/0.33 | 0.40/0.60 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4137 | 0.35/0.40 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4140 | 0.38/0.43 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4142 | 0.40/0.45 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4145 | 0.43/0.48 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4147 | 0.45/0.50 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4150 | 0.48/0.53 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4161 | 0.56/0.64 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | 0.25/0.35 |

| AISI 4320 | 0.17/0.22 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | 0.40/0.60 | 0.20/0.30 |

| AISI 4340 | 0.38/0.43 | 0.60/0.80 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | 0.70/0.90 | 0.20/0.30 |

| AISI 4419 | 0.18/0.23 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | — | — | 0.45/0.60 |

| AISI 4615 | 0.13/0.18 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | — | 0.20/0.30 |

| AISI 4620 | 0.17/0.22 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | — | 0.20/0.30 |

| AISI 4621 | 0.18/0.23 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | — | 0.20/0.30 |

| AISI 4626 | 0.24/0.29 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 0.70/1.00 | — | 0.15/0.25 |

| AISI 4718 | 0.16/0.21 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.90/1.20 | 0.35/0.55 | 0.30/0.40 |

| AISI 4720 | 0.17/0.22 | 0.50/0.70 | 0.035 | 0.040 | 0.20/0.35 | 0.90/1.20 | 0.35/0.55 | 0.15/0.25 |

| AISI 4815 | 0.13/0.18 | 0.40/0.60 | 0.035 | 0.040 | 0.20/0.35 | 3.25/3.75 | — | 0.20/0.30 |

| AISI 4817 | 0.15/0.20 | 0.40/0.60 | 0.035 | 0.040 | 0.20/0.35 | 3.25/3.75 | — | 0.20/0.30 |

| AISI 4820 | 0.18/0.23 | 0.50/0.70 | 0.035 | 0.040 | 0.20/0.35 | 3.25/3.75 | — | 0.20/0.30 |

| AISI 5120 | 0.17/0.22 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5130 | 0.28/0.33 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | — |

| AISI 5132 | 0.30/0.35 | 0.60/0.80 | 0.035 | 0.040 | 0.20/0.35 | — | 0.75/1.00 | — |

| AISI 5135 | 0.33/0.38 | 0.60/0.80 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.05 | — |

| AISI 5140 | 0.38/0.43 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5145 | 0.43/0.48 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5147 | 0.46/0.51 | 0.70/0.95 | 0.035 | 0.040 | 0.20/0.35 | — | 0.85/1.15 | — |

| AISI 5150 | 0.48/0.53 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5155 | 0.51/0.59 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 6150 | 0.48/0.53 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15 min. |

| AISI 8615 | 0.13/0.18 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8617 | 0.15/0.20 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8620 | 0.18/0.23 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8622 | 0.20/0.25 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8625 | 0.23/0.28 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8627 | 0.25/0.30 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8630 | 0.28/0.33 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8637 | 0.35/0.40 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8640 | 0.38/0.43 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8642 | 0.40/0.45 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8645 | 0.43/0.48 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8655 | 0.51/0.59 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8720 | 0.18/0.23 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.20/0.30 |

| AISI 8740 | 0.38/0.43 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.20/0.30 |

| AISI 8822 | 0.20/0.25 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.30/0.40 |

| AISI 9254 | 0.51/0.59 | 0.60/0.80 | 0.035 | 0.040 | 1.20/1.60 | 0.60/0.80 | — | — |

| AISI 9255 | 0.51/0.59 | 0.70/0.95 | 0.035 | 0.040 | 1.80/2.20 | — | — | — |

| AISI 9260 | 0.56/0.64 | 0.75/1.00 | 0.035 | 0.040 | 1.80/2.20 | — | — | — |

Grades shown in the above list with prefix letter E are normally made only by the basic electric furnace process. All others are normally manufactured by the basic open hearth or basic oxygen processes but may be manufactured by the basic electric furnace process with adjustments in phosphorus and sulphur.

>AISI 4130 Stock & AISI 4130 High Pressure Manifold Fittings Price

- astm a519 4130 seamless steel pipe

US $750-1050 / Ton (FOB Price)

- 4130 seamless pipe

US $452-800 / Metric Ton (FOB Price)

- Cold Drawn and Cold Drawn aisi 4130 seamless pipe

US $1000-1800 / Metric Ton (FOB Price)

- SAE 4130 seamless pipe

US $900-1600 / Ton (FOB Price)

- AISI 4130 seamless pipe for fluid

US $600-900 / Ton (FOB Price)

- High standard astm a519 4130 seamless steel pipe

US $600-700 / Ton (FOB Price)

- AISI 4130 butt welding eccentric reducer

US $0.5-8000 / Piece (FOB Price)

- 4130 Butt welded pipe fittings elbow tee reducer

US $1-100 / Piece (FOB Price)

- 4130 fittings ASTM A105 Stainless Steel Seamless Butt Weld Fittings

US $1-10000 / Piece (FOB Price)

- SAE 4130 Steel Forged Pipe Fittings

US $1-1000 / Piece (FOB Price)

- API 6A Hammer union FITTING

US $30.00-31.00 / Set (FOB Price)

- aisi 304 seamless stainless steel pipe & fitting

US $2000-4000 / Ton (FOB Price)

- 4130 Branch fittings

US $2000-4000 / Ton (FOB Price)

- SAE-AISI 4130 FLANGES

US $1-100000 / Piece (FOB Price)

- Forged 4130 flange

US $1000-1450 / Ton (FOB Price)

- 4130 flange

US $0.5-5000 / Piece (FOB Price)

- Low alloy steel 4130 flange

US $1-100 / Piece (FOB Price)

- ASTM A 788 GR 4130; API 6A TYPE 6 BX FLANGE

US $0.3-900 / Piece (FOB Price)

- 4130 connecting flange

US $1000-2000 / Metric Ton (FOB Price)

- alloy steel 4130 Threaded flange

US $1-1000 / Piece (FOB Price)

- 4130 thread flanges

US $0.15-10 / Piece (FOB Price)

- low price rtj flange 10000 psi in aisi 4130

US $1-500 / Piece (FOB Price)

- AISI/SAE 4130 Seamless Tubes Pipes AISI/SAE 4140 Seamless Tubes Pipes

US $600-700 / Ton (FOB Price)

- High quality aisi 4130 alloy seamless steel pipe tube, sae 4130

US $500-1000 / Ton (FOB Price)

- AISI 4130 Seamless Steel Pipe & Tube

US $600-1100 / Ton (FOB Price)

- Heat resistant aisi 4130 seamless tube

US $1000-5500 / Ton (FOB Price)

- Cold finished aisi 4130 seamless steel tube

US $1000-1800 / Metric Ton (FOB Price)

- ASTM API Standard aisi 4130 seamless steel tube

US $3.5-10 / Kilogram (FOB Price)

- SCH 40 carbon seamless steel tube / AISI/SAE 4130 Seamless Tubes & Pipes

US $500-1000 / Ton (FOB Price)

- ASTM A519 4130, AISI 4130 Seamless Steel Tube supplier

US $600-1000 / Ton (FOB Price)

- 4130 chromoly precision seamless tube

US $800-1300 / Ton (FOB Price)

- Cold Drawn 4130 seamless steel tubes for mechanical

US $1000-1200 / Ton (FOB Price)

- 2014 new sae 4130 alloy seamless steel pipe and tube

US $1000-3000 / Ton (FOB Price)

- a519 precision seamless steel tube with 4130 material

US $1000-5500 / Ton (FOB Price)

- 4130 chrome moly precision seamless steel tubing

US $1500-2500 / Ton (FOB Price)

- Chrome Moly Steel Tubing

US $1000-1999 / Ton (FOB Price)

- chrome moly alloy 4130 steel tube

US $910-970 / Ton (FOB Price)

- Precision Chrome Moly Alloy Steel Tube 4130 / 4140 / 30CrMo4 / 42CrMo4

US $1000-2000 / Metric Ton (FOB Price)

- High precision chrome moly steel

US $1800-2100 / Ton (FOB Price)

- 25mm chrome steel tube

US $860-1060 / Ton (FOB Price)