Alloy Steel AISI 4130 Spectacle Blinds, Also stock AISI 4130 Pipe Fittings & Flanges.

AISI 4130 Spectacle Blinds suppliers and manufacturer in India, buy any quantity & size at best price

Contents-

1. AISI 4130 Spectacle Blinds Specification

2. AISI 4130 Spectacle Blinds Packaging & Shipping

3. AISI 4130 other Alloy Steel Products

Get QUICK QUOTE now (best price guaranteed)

MD Exports LLP takes immense pleasure in Introducing itself as a Stockiest & Exporter of Alloy Steel AISI 4130 Spectacle Blinds, AISI 4130 Flanges, API Flanges & AISI 4130 Fittings. MD Exports LLP regularly supplies AISI 4130 Spectacle Blinds to core industries such as refineries, chemical & petrochemical, oil & Gas, Water treatment plant, power plants, off-shore, ship building, EPC & other Engineering company. We can supply AISI 4130 Spectacle Blinds & LONG SWEEP MANIFOLD REINFORCED FITTINGS Suitable for 5000, 10000 & 15000PSI Applications. We have ready stock of 4130 Grade Fittings, Tees & Olets (Origin America / German) etc. We also stock 10,000 psi API6BX blind and weld neck flanges in 4130 (or 410 stainless) grade in 60K and 75K.

MD Exports LLP takes immense pleasure in Introducing itself as a Stockiest & Exporter of Alloy Steel AISI 4130 Spectacle Blinds, AISI 4130 Flanges, API Flanges & AISI 4130 Fittings. MD Exports LLP regularly supplies AISI 4130 Spectacle Blinds to core industries such as refineries, chemical & petrochemical, oil & Gas, Water treatment plant, power plants, off-shore, ship building, EPC & other Engineering company. We can supply AISI 4130 Spectacle Blinds & LONG SWEEP MANIFOLD REINFORCED FITTINGS Suitable for 5000, 10000 & 15000PSI Applications. We have ready stock of 4130 Grade Fittings, Tees & Olets (Origin America / German) etc. We also stock 10,000 psi API6BX blind and weld neck flanges in 4130 (or 410 stainless) grade in 60K and 75K.

API Licensed Manufacturers usually use 4130 for all of their 6BX connectors especially weld neck connectors (flanges and hubs). Steels other than 4130 that manufacturers may use, include 4140, 8630, and 410 “Stainless Steel.” All of these materials prove more difficult than 4130 to weld, they almost can’t be welded satisfactorily in the field. Of the commonly available low alloy steels, AISI 4130 Spectacle Blinds & 4130 has the best weldability.

AISI 4130 Spectacle Blinds Specification

We accept all small/large quantity orders.

Description of AISI 4130 Spectacle Blinds

- Type: AISI 4130 Spectacle Blinds

- Flanges Type:

- Alloy Steel AISI 4130 Forged Flanges ANSI B16.5 (Size 15 NB to 750 NB)

- Alloy Steel AISI 4130 Plate Flanges ANSI B16.5 (15 NB to 500 NB)

- Material: Alloy Steel AISI 4130, AISI 4140, AISI 4130 Spectacle Blinds

- Standard: ANSI,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI ,AS2129,GOST-12820

- Size: 1/2-78 inch (DN15-DN2000)

- Pressure: ANSI class 150,300,600,1500,2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

- Test Certificate: Manufacturer Test Certificate, IBR Test Certificate (Form III-C), Under Third Party Inspection

- Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

- Usage: AISI 4130 Spectacle Blinds mostly used in Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc.

AISI 4130 Spectacle Blinds Dimension

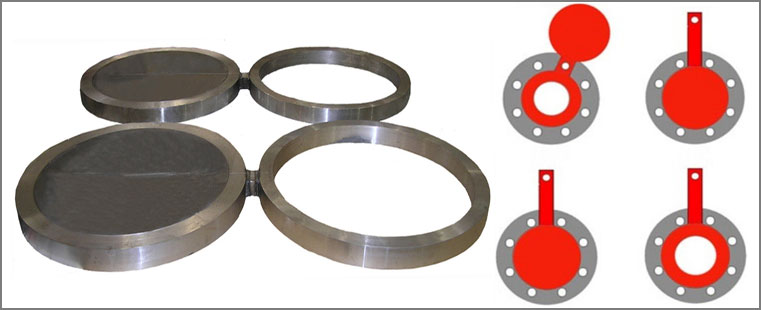

Spectacle Blind Flange is generally a piece of metal that is cut to fit between two pipe flanges and usually sandwiched between two gaskets. A spectacle blind is often made from two metal discs that are attached to each other by a small section of steel. The shape is similar to a pair of glasses or “spectacles” – hence the name spectacle blind.

These Flanges are available in the following range.

Alloy Steel: AISI 4130, ASTM a182 F1, F11, F22, F5, F9, F91

Dimensional Standard

ANSI: ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638, DIN 2673

B.S: BS 4504, BS4504, BS1560, BS10

Quality Control:-

1- Tensile Testing

2- Impact Testing

3-Hardness Testing

4- Dimensional Verification

5- Traceability

6- chemical analysis

7- visual examination

8- surface NDE

9- Weld NDE-General

10- NDE Volumetric

11- Hydrostatic Test

12- Gas Test

13- Drift Test

14- Documentation

15- MR-01-75

Click on below for AISI 4130 Spectacle Blinds Specification:

- AISI 4130 Flanges

- AISI 4130 Weld Neck Flanges

- AISI 4130 Companion Flanges

- AISI 4130 Forged Flanges

- AISI 4130 Blind Flanges

- AISI 4130 Spectacle Blinds

- AISI 4130 High Hub Blinds

- AISI 4130 Orifice Flanges

- AISI 4130 Slip-on Flanges

- AISI 4130 Socket Weld Flanges

- AISI 4130 Flat Flanges

- AISI 4130 Loose Flanges

- AISI 4130 Threaded Flanges

- AISI 4130 Lapped joint Flanges

- AISI 4130 Reducing Flanges

- AISI 4130 Square Flanges

- AISI 4130 Groove & Tongue Flanges

- AISI 4130 Long Neck Weld Flanges

- AISI 4130 Screwed Flanges

- AISI 4130 Ring Type Joint Flanges

- AISI 4130 RTJ Flanges

- AISI 4130 API 6A and ANSI forged swivel flanges

CONTACT US FOR A QUICK QUOTE

Get AISI 4130 Spectacle Blinds price list, send an email to us at [email protected],AISI 4130 Spectacle Blinds quality certificates

AISI 4130 Spectacle Blinds delivered with Mill Test Certificate EN 10204/3.1B

AISI 4130 Spectacle Blinds Packaging & Shipping

AISI 4130 Spectacle Blinds Packing: We focus on every procedure to assure quality, the package we usually take is pack AISI 4130 Spectacle Blinds with environmental poly bags, and then in free fumigation wooden cases or wooden palte. Also can accept customized package such as OEM by negotiation.

MD Exports LLP offers just about everything to meet your special flange pack requirements.

AISI 4130 Spectacle Blinds Marking: All flanges are marked with size, cast number and specification. Or as per customer’s requirement;

Packing Type for Alloy Steel AISI 4130 SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing Flanges

AISI 4130 Spectacle Blinds Inner packing

AISI 4130 Spectacle Blinds Outer packing

So, besides the fact that we can arrange freight transportation for you, we can before that:

- specifically mark parts or packages;

- provide for a special packing according to what is required by the shipping method or by you.

We mark the AISI 4130 Spectacle Blinds as needed with the most suitable marking technique.

When packaging and packing, our experienced warehouse staff systematically takes the greatest precautions for your AISI 4130 Spectacle Blinds to be optimally protected during transportation. We pack the AISI 4130 Spectacle Blinds according to the appropriate method: strapped pallet, wooden crate, overseas packing (ISPM15).

>AISI 4130 other Alloy Steel Products

- AISI 4130 Pipes

- AISI 4130 SEAMLESS Pipes

- ASTM A519 4130 Pipes

- ASTM A519 4130 SEAMLESS Pipes

- AISI 4130 75K SEAMLESS Pipes

- AISI 4130 DRILLING Pipes

- 4130 Tubes

- AISI 4130 Tubes

- AISI 4130 SEAMLESS Tubes

- AISI 4130 L 80 SEAMLESS Tubes

- A519 4130 Seamless Alloy Steel Tube

- 4130 Tubing

- Chrome Moly Tubing 4130

- 4130 ALLOY STEEL ROUND SEAMLESS TUBING

- Alloy Steel 4130 Round Tubing

- 4130 Aircraft Tubing

- 4130 seamless tubing

- 4130 Steel Rectangular Tubing

- ASTM A519 4130 Mechanical Tubing

- AISI 4130 Flanges

- Alloy Steel AISI 4130 Fittings

- AISI 4130 API Flanges

>AISI 4130 Spectacle Blinds Useful info

AISI 4130 Alloy Steel (UNS G41300)

Alloy steels are designated by AISI four-digit numbers. They are more responsive to mechanical and heat treatments than carbon steels. They comprise different types of steels with compositions which exceed the limitations of B, C, Mn, Mo, Ni, Si, Cr, and Va in the carbon steels.

AISI 4130 alloy steel contains chromium and molybdenum as strengthening agents. It has low carbon content, and hence it can be welded easily. The datasheet given below provides more details about AISI 4130 alloy steel.

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low-alloy steels and high-alloy steels.

Specifications

| Standard | Alloy Steel |

|---|---|

| AISI 4130 Alloy Steel | UNS G41300 |

| AISI 4340 Alloy Steel | UNS G43400 |

| AISI 4140 Alloy Steel | UNS G41400 |

| AISI 8620 Alloy Steel | UNS G86200 |

| AISI 4130 (Chromoly) Normalized Alloy Steel (available in Round, Sheet, Tube) | ||

|---|---|---|

| Minimum Properties | Ultimate Tensile Strength, psi | 97,200 |

| Yield Strength, psi | 63,100 | |

| Elongation | 25.5% | |

| Rockwell Hardness | B92 | |

| 4130 (Chromoly) Annealed Alloy Steel | ||

| Minimum Properties | Tensile Strength, psi | 81,200 |

| Yield Strength, psi | 52,200 | |

| Elongation | 28.2% | |

| Rockwell Hardness | B82 | |

| Chemistry | Iron (Fe) | 97.3 – 98.22% |

| Carbon (C) | 0.28 – 0.33% | |

| Chromium (Cr) | 0.8 – 1.1% | |

| Manganese (Mn) | 0.4 – 0.6% | |

| Molybdenum (Mo) | 0.15 – 0.25% | |

| Phosphorus (P) | 0.035% max | |

| Sulphur (S) | 0.04% max | |

| Silicon (Si) | 0.15 – 0.35% | |

Alloy Steel Chemical Composition

|

Chemical Composition Ranges and Limits, percent |

||||||||

| AISI Number |

C |

Mn |

P Max. |

S Max. |

Si |

Ni |

Cr |

Mo |

|---|---|---|---|---|---|---|---|---|

| AISI 4130 | 0.28/0.33 | 0.40/0.60 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4137 | 0.35/0.40 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4140 | 0.38/0.43 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4142 | 0.40/0.45 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4145 | 0.43/0.48 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4147 | 0.45/0.50 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4150 | 0.48/0.53 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15/0.25 |

| AISI 4161 | 0.56/0.64 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | 0.25/0.35 |

| AISI 4320 | 0.17/0.22 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | 0.40/0.60 | 0.20/0.30 |

| AISI 4340 | 0.38/0.43 | 0.60/0.80 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | 0.70/0.90 | 0.20/0.30 |

| AISI 4419 | 0.18/0.23 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | — | — | 0.45/0.60 |

| AISI 4615 | 0.13/0.18 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | — | 0.20/0.30 |

| AISI 4620 | 0.17/0.22 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | — | 0.20/0.30 |

| AISI 4621 | 0.18/0.23 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 1.65/2.00 | — | 0.20/0.30 |

| AISI 4626 | 0.24/0.29 | 0.45/0.65 | 0.035 | 0.040 | 0.20/0.35 | 0.70/1.00 | — | 0.15/0.25 |

| AISI 4718 | 0.16/0.21 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.90/1.20 | 0.35/0.55 | 0.30/0.40 |

| AISI 4720 | 0.17/0.22 | 0.50/0.70 | 0.035 | 0.040 | 0.20/0.35 | 0.90/1.20 | 0.35/0.55 | 0.15/0.25 |

| AISI 4815 | 0.13/0.18 | 0.40/0.60 | 0.035 | 0.040 | 0.20/0.35 | 3.25/3.75 | — | 0.20/0.30 |

| AISI 4817 | 0.15/0.20 | 0.40/0.60 | 0.035 | 0.040 | 0.20/0.35 | 3.25/3.75 | — | 0.20/0.30 |

| AISI 4820 | 0.18/0.23 | 0.50/0.70 | 0.035 | 0.040 | 0.20/0.35 | 3.25/3.75 | — | 0.20/0.30 |

| AISI 5120 | 0.17/0.22 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5130 | 0.28/0.33 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | — |

| AISI 5132 | 0.30/0.35 | 0.60/0.80 | 0.035 | 0.040 | 0.20/0.35 | — | 0.75/1.00 | — |

| AISI 5135 | 0.33/0.38 | 0.60/0.80 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.05 | — |

| AISI 5140 | 0.38/0.43 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5145 | 0.43/0.48 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5147 | 0.46/0.51 | 0.70/0.95 | 0.035 | 0.040 | 0.20/0.35 | — | 0.85/1.15 | — |

| AISI 5150 | 0.48/0.53 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 5155 | 0.51/0.59 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.70/0.90 | — |

| AISI 6150 | 0.48/0.53 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | — | 0.80/1.10 | 0.15 min. |

| AISI 8615 | 0.13/0.18 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8617 | 0.15/0.20 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8620 | 0.18/0.23 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8622 | 0.20/0.25 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8625 | 0.23/0.28 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8627 | 0.25/0.30 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8630 | 0.28/0.33 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8637 | 0.35/0.40 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8640 | 0.38/0.43 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8642 | 0.40/0.45 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8645 | 0.43/0.48 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8655 | 0.51/0.59 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.15/0.25 |

| AISI 8720 | 0.18/0.23 | 0.70/0.90 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.20/0.30 |

| AISI 8740 | 0.38/0.43 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.20/0.30 |

| AISI 8822 | 0.20/0.25 | 0.75/1.00 | 0.035 | 0.040 | 0.20/0.35 | 0.40/0.70 | 0.40/0.60 | 0.30/0.40 |

| AISI 9254 | 0.51/0.59 | 0.60/0.80 | 0.035 | 0.040 | 1.20/1.60 | 0.60/0.80 | — | — |

| AISI 9255 | 0.51/0.59 | 0.70/0.95 | 0.035 | 0.040 | 1.80/2.20 | — | — | — |

| AISI 9260 | 0.56/0.64 | 0.75/1.00 | 0.035 | 0.040 | 1.80/2.20 | — | — | — |

Grades shown in the above list with prefix letter E are normally made only by the basic electric furnace process. All others are normally manufactured by the basic open hearth or basic oxygen processes but may be manufactured by the basic electric furnace process with adjustments in phosphorus and sulphur.

>AISI 4130 Stock & AISI 4130 Spectacle Blinds Price

- astm a519 4130 seamless steel pipe

US $750-1050 / Ton (FOB Price)

- 4130 seamless pipe

US $452-800 / Metric Ton (FOB Price)

- Cold Drawn and Cold Drawn aisi 4130 seamless pipe

US $1000-1800 / Metric Ton (FOB Price)

- SAE 4130 seamless pipe

US $900-1600 / Ton (FOB Price)

- AISI 4130 seamless pipe for fluid

US $600-900 / Ton (FOB Price)

- High standard astm a519 4130 seamless steel pipe

US $600-700 / Ton (FOB Price)

- AISI 4130 butt welding eccentric reducer

US $0.5-8000 / Piece (FOB Price)

- 4130 Butt welded pipe fittings elbow tee reducer

US $1-100 / Piece (FOB Price)

- 4130 fittings ASTM A105 Stainless Steel Seamless Butt Weld Fittings

US $1-10000 / Piece (FOB Price)

- SAE 4130 Steel Forged Pipe Fittings

US $1-1000 / Piece (FOB Price)

- API 6A Hammer union FITTING

US $30.00-31.00 / Set (FOB Price)

- aisi 304 seamless stainless steel pipe & fitting

US $2000-4000 / Ton (FOB Price)

- 4130 Branch fittings

US $2000-4000 / Ton (FOB Price)

- SAE-AISI 4130 FLANGES

US $1-100000 / Piece (FOB Price)

- Forged 4130 flange

US $1000-1450 / Ton (FOB Price)

- 4130 flange

US $0.5-5000 / Piece (FOB Price)

- Low alloy steel 4130 flange

US $1-100 / Piece (FOB Price)

- ASTM A 788 GR 4130; API 6A TYPE 6 BX FLANGE

US $0.3-900 / Piece (FOB Price)

- 4130 connecting flange

US $1000-2000 / Metric Ton (FOB Price)

- alloy steel 4130 Threaded flange

US $1-1000 / Piece (FOB Price)

- 4130 thread flanges

US $0.15-10 / Piece (FOB Price)

- low price rtj flange 10000 psi in aisi 4130

US $1-500 / Piece (FOB Price)

- AISI/SAE 4130 Seamless Tubes Pipes AISI/SAE 4140 Seamless Tubes Pipes

US $600-700 / Ton (FOB Price)

- High quality aisi 4130 alloy seamless steel pipe tube, sae 4130

US $500-1000 / Ton (FOB Price)

- AISI 4130 Seamless Steel Pipe & Tube

US $600-1100 / Ton (FOB Price)

- Heat resistant aisi 4130 seamless tube

US $1000-5500 / Ton (FOB Price)

- Cold finished aisi 4130 seamless steel tube

US $1000-1800 / Metric Ton (FOB Price)

- ASTM API Standard aisi 4130 seamless steel tube

US $3.5-10 / Kilogram (FOB Price)

- SCH 40 carbon seamless steel tube / AISI/SAE 4130 Seamless Tubes & Pipes

US $500-1000 / Ton (FOB Price)

- ASTM A519 4130, AISI 4130 Seamless Steel Tube supplier

US $600-1000 / Ton (FOB Price)

- 4130 chromoly precision seamless tube

US $800-1300 / Ton (FOB Price)

- Cold Drawn 4130 seamless steel tubes for mechanical

US $1000-1200 / Ton (FOB Price)

- 2014 new sae 4130 alloy seamless steel pipe and tube

US $1000-3000 / Ton (FOB Price)

- a519 precision seamless steel tube with 4130 material

US $1000-5500 / Ton (FOB Price)

- 4130 chrome moly precision seamless steel tubing

US $1500-2500 / Ton (FOB Price)

- Chrome Moly Steel Tubing

US $1000-1999 / Ton (FOB Price)

- chrome moly alloy 4130 steel tube

US $910-970 / Ton (FOB Price)

- Precision Chrome Moly Alloy Steel Tube 4130 / 4140 / 30CrMo4 / 42CrMo4

US $1000-2000 / Metric Ton (FOB Price)

- High precision chrome moly steel

US $1800-2100 / Ton (FOB Price)

- 25mm chrome steel tube

US $860-1060 / Ton (FOB Price)