Stainless Steel 301 Hex Bar Manufacturers, Stainless Steel 301 Hex Bar Exporters, Stainless Steel 301 Hex Bar Suppliers, Stainless Steel 301 Hex Bar Importers, Stainless Steel 301 Hex Bar Stockists

Stainless Steel 301 Hex Bar Manufacturers In Banglore, Stainless Steel 301 Hex Bar Exporters In Banglore, Stainless Steel 301 Hex Bar Suppliers In Banglore, Stainless Steel 301 Hex Bar Importers In Banglore, Stainless Steel 301 Hex Bar Stockists In Banglore

Stainless Steel 301 Hex Bar Manufacturers in India, Stainless Steel 301 Hex Bar Exporters in India, Stainless Steel 301 Hex Bar Suppliers in India, Stainless Steel 301 Hex Bar Importers in India, Stainless Steel 301 Hex Bar Stockists in India

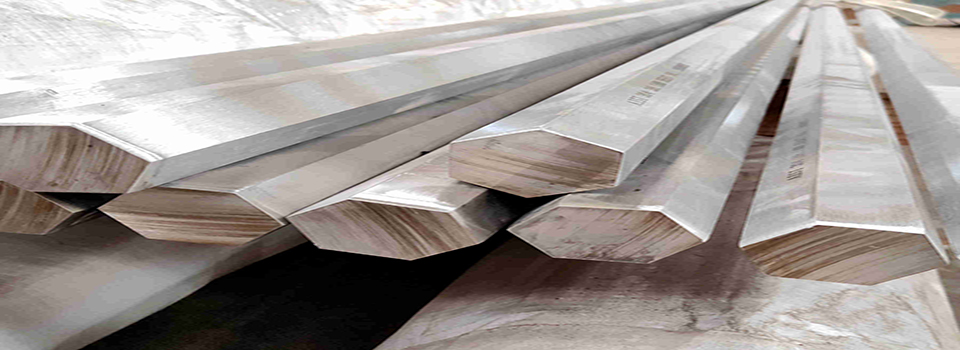

Stainless Steel Hex Bars, CS Hexagonal Bars, Duplex Stainless Steel Hex Bars, SS Hexagonal Bars Supplier & Manufacturer, Nickel Alloy Hex Bars, Alloy Steel Hexagonal Bar, Carbon Steel Hex Bars, Hexagonal Bar Manufacturer In India.301 Stainless Steel Bar rod manufacturer 301 Stainless Steel Bar rod suppliers 301 Stainless Steel Bar rod stockists 301 Stainless Steel Bar rod exporter Mumbai

The SSS Stainless Steel. & Engg. Co. is a known creator and exporter of Stainless Steel 301 Hexagon Bars, which has satisfactory to contradict chloride molecule stress disintegration parting, and an altogether consistent austenite structure. The mixture structure of our SS 301 Metric Hex Bars is expected to give remarkable assurance from a huge amount of damaging conditions.

These Type 301 Hex Bars has superb insurance from both decreasing and oxidizing acids like sulfuric and phosphoric, and keeps up a vital good ways from weight disintegration parting. Utilization safe uses of our Grade 301 Hex Bars is the invention and petrochemical, air pollution control, sustenance getting ready, toward the ocean oil and gas age, nuclear, oil refining, mineral dealing with, steel pickling and waste exchange undertakings. The chromium and molybdenum substance of these AISI 301 Hex Bars gives security from chloride setting, similarly as insurance from a grouping of oxidizing conditions.

The steel content in our 301 Stainless Steel Hexagon Bar is satisfactory for insurance from chloride-molecule stress-utilization parting. Regular livelihoods of these Stainless Steel UNS S30100 Hex Bars are Oil & gas applications, pickling parts, and engineered taking care of.

Our SUS 301 Hex Bars can be speedily welded by the secured metal-bend method using composite welding anode 135, the gas ensured round section strategies using blend filler metal 65, and the deterrent welding structures. These Stainless Steel Din 1.4305 Hex Bars is the pioneer of immense quantities of the Molybdenum containing nickel iron chromium mixes which have seen organization over the past century.

Stainless Steel 301 Hex Bar Specification

| Standard | ASTM A276 / A479, ASME SA276 / A479 |

| Size | 14mm-300mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

Equivalent Grades of SS 301 Hex Bar

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | SS | AFNOR | EN |

| SS 301 | 1.4310 | S30100 | SUS 301 | 301S21 | 2331 | - | X10CrNi18-8 |

Stainless Steel 301 Hex Bar Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 301 | 0.15 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16 – 18 | - | 6 – 8 | 0.10 max |

Mechanical Properties of SS 301 Hex Bar

| Density | Melting Point | Tensile Strength | Yield Strength 0.2% Proof | Elongation (% in 50mm) (thick.>0.76mm) |

| 7.8 g/cm3 | 1399 – 1421 °C (2250 – 2590 °F) | 758 (MPa) min. | 276 (MPa) min. | 60 min. |

Application

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry