Inconel 600 /601 Flanges

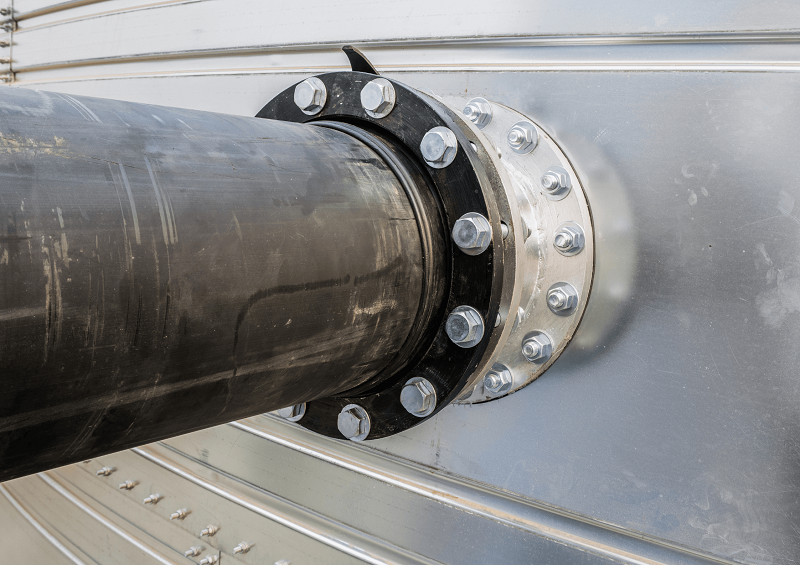

A flange is an external or internal rim in between the two pipes. Inconel 600/601 flange provides connectivity to the pipes, valves, pumps, and other equipment to form an overall powerful piping system. Aluminum Alloys can source and stock a wide range of premium quality Inconel 600 and 601 Flanges.

Inconel 600/601 provides good oxidation endurance at higher temperature surroundings. Flanges provide better connectivity to the pipes and maintain the positionings of the rails. Inconel 600/601 Flanges addresses the highest level of strength, durability, and reliability of the piping system within the industries.

The demands for Inconel 600/601 Flanges are pretty high in the market. All our flanges provide greater endurance to the highest standards.

APPLICATIONS OF INCONEL 600/601 FLANGES IN VARIOUS INDUSTRIES

In various industries, especially oil and gas companies, engineers need to seal and secure the components inside the pipes or cylinders from the pressure and compositions of outside substances. They do this by fastening two pieces of metal or other material elements with the bolts on the lip. That 'lip' is a flange.

Inconel 600/601 can alloy quickly with various metals such as copper, iron, chromium, or molybdenum. It makes the job easy for flanges to collaborate with different machinery that you will find in various chemical processing industries.

Selecting the perfect type of flanges depends mainly on the industrial types and their overall piping systems. But let's first check out where exactly we can find Inconel 600/601 Flanges usable:

A. OIL AND GAS INDUSTRIES

B. PAPER AND PULP INDUSTRIES

C. FOOD PROCESSING INDUSTRIES

D. PETROCHEMICAL INDUSTRIES

E. NUCLEAR POWER PLANT INDUSTRIES

Specification

Specifications : ASTM B564 / ASME SB564

Size : 1/2″NB TO 60″NB

Standards : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Standard :ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Form :Orifice Flanges, Slip on Flanges (SORF), Spectacle Blind Flanges, Forged Flanges, Threaded Flanges, Blind Flanges, Socket weld Flanges, Lap Joint Flanges, Ring Type Joint Flanges, Spacer Ring Flanges, Plate Flanges, Long weld Neck Flanges, Nipo Flange, Nipolet Flanges, Weld neck Flanges (WNRF), Flat Flange

KEY PROPERTIES OF INCONEL 600/601 FLANGES

DIFFERENT FORMS OF INCONEL 600/601 FLANGES AVAILABLE IN THE MARKET

Inconel 600/601 Flanges inherits the properties of Inconel alloys, which are a mixture of nickel and chromium. Inconel is resistant to oxidation and works wonderfully in manufacturing and processing industries.

At Aluminum Alloys, we have various forms of Inconel 600/601 Flanges in our warehouse, that includes:

We source and supply many different types of flanges, some of which we have detailed below:

1. RING TYPE JOINT FLANGES

These types are the most suitable flanges in the pipeline design of any industry. They are circular and have small-circular cuts on their surfaces with steel ring gaskets. While tightening the bolts of the flanges, the gaskets are squeezed, creating a tight and leak-proof seal.

Many industries opt for Ring-Type Joint Flanges, as the channel within the flanges ensures the ring centres itself when the bolts are tight. Technically, Gas and Oil Industries uses this flange type on various equipment like valves, pipeline assemblies, high-pressure vessel joints, etc.

2. RAISED FACE TYPE FLANGE

Raised Face type Flanges are the alternative of the Ring-Type Joint Flanges. They are circular, and their gasket lies above the bolting circle face. You will find them implanted on applications where the concentration of pressure is higher.

This type of flange is highly versatile. We can use them collaboratively with other gasket designs, such as flat ring type sheets and metallic compositions.

3. WELD NECK FLANGES

Weld Neck Flanges are also known as High Hub Flanges or Tapered Hub Flanges. They are circular and consist of an extended rim above their surface. Technically, they must be shaped and there-after butt-wielded to a pipe.

You will find the Weld Neck Flanges in the heating generating surroundings like mining, pharmaceuticals, or nuclear power plants. In a nutshell, one needs to install these flanges where pressure rises to 5000 psi.

4. BLIND FLANGES

For blocking or closing the lid or nozzle of a pipe, we use a plate-type surface known as Blind Flanges. It creates a covering on the vessel that is not useful for a particular period.

It also creates easy access to the pipelines if we need to reopen them. It can hold high-pressure components and blocks uncertain leakages. Blink Flanges can either be Raised Face (RF) or Flat Face (FF). They are helpful in many industries such as petrochemical, pipe engineering, waterworks, etc.

5. SLIP-ON FLANGES

Slip-On Flanges are popularly known as SO Flanges. SO Flanges are typically designed to fit a pipe into the inner hole of the flange. Thus, you will find that their inside diameter is greater than the pipe's outer diameter.

Slip-On Flanges installs a pipe via a 'fillet weld' from every angle of the flange, which assures stability and strength of the joins. This flange type is ideal for lower pressure applications. They have a lower material cost than the weld neck flanges.

MARKINGS AND PACKAGINGS

Product packaging serves to protect the products inside. Aluminum Alloys effectively ensures all the products are deliverable to our clients securely. In the case of exports, we follow all international standard protocols of packaging.

Often, we export them in wooden cases. We mark our products with Grades, Lot Numbers, Size, Degree, and our Trademark. We also make custom markings on the products as per the requirements of our clients.

QUALITY ASSURANCE

At Aluminum Alloys, all products are subject to strict supervision at each production chain, right from purchasing the raw materials to dispatching products. All the processes undergo inspections for conformity to ASTM, ASME, MSS, and JIS codes and standards.

Mumbai, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Bhopal, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Vijayawada, Madurai, Varanasi, Meerut, Faridabad, Rajkot, Jamshedpur, Srinagar, Jabalpur, Asansol, Vasai Virar City, Allahabad, Dhanbad, Aurangabad, Amritsar, Jodhpur, Ranchi, Raipur, Kollam, Gwalior, Durg-Bhilainagar, Chandigarh, Tiruchirappalli, Kota

Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Afghanistan, Albania, Andorra, Austria, Bahrain, Bangladesh, Bhutan, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, North Korea, Netherlands, Norway, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Sri Lanka, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Vietnam, Yemen

Copyright © 2018 Aluminum Alloys.

Disclaimer : Inconel, Monel & Hastelloy are registered trademark of specific manufacturer, name are listed for the reference to help in identifying the grade.

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela