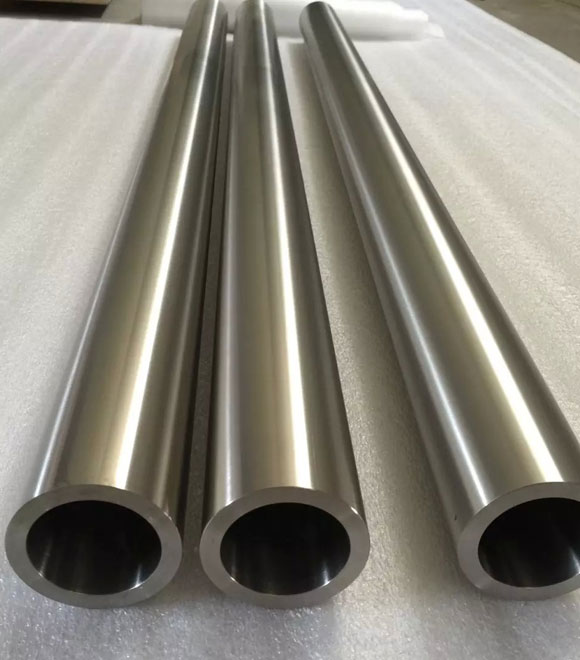

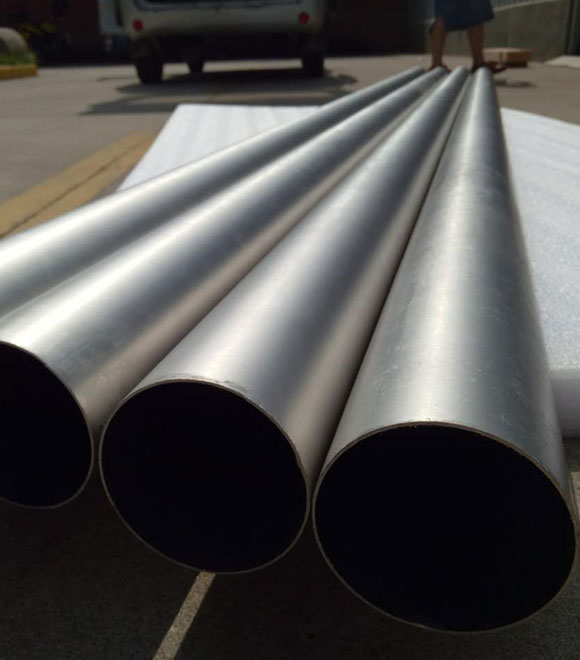

Incoloy 330/ SS 330/ Ra 330 Pipe & Tubes

Incoloy 330 Tubing, Incoloy 330 Pipes, Incoloy 330 seamless tube, RA 330 Tubing, Incoloy 330/ SS 330/ Ra 330 Pipe, Incoloy Ra 330 Hexagonal Pipe Exporter in India

We manufacture & Supplier of highest quality corrosion and temperature resistant Incoloy 330 Tubing. We supply precision smooth bore Incoloy 330 Pipes & tubes for marine environments, brackish water, bleaching operations, closed loop water systems and some food processing applications. Incoloy Alloy 330 Pipes & Tube (Incoloy Alloy 330, 1.4886, UNS N08330) was an alloy known as MISCO metal, it was a rolled version of the cast HT alloy and 35% nickel, 15% chromium. Ra 330 Tubes is produced for applications in high temperature industrial environments where good resistance to the combined effects of carburization and thermal cycling are required. Inconel 330 Seamless Pipes (UNS N08330) is an austenitic alloy with good high – temperature strength and corrosion resistance.

ASME SB546 Welded Incoloy Pipes, ASTM B710 Incoloy Pipes, SS 330 Incoloy Hollow Pipe, DIN 1.4886 Incoloy Pipe, UNS N08330 Pipe, SS 330 Incoloy Seamless Pipes

Specification

Specifications : ASTM B535, B546, B710 ASME SB535, SB546, SB710

Size : 15″NB TO 150″NB IN

Schedule :SCH5, SCH10, SCH40, STD, SCH80, SCH160

Form : Round Pipes & Tubes, Square Pipes & Tubes, Rectangular Pipes & Tubes

Type : Seamless / ERW / EFW / Welded / Fabricated

Length : Single Random, Double Random & Cut Length

End : Plain End, Beveled End, Threaded

Outside Finish : 2B, No.1, No.4, No.8 Mirror Finish

Finish : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

High-performance nickel alloys for sour oil and gas fields. Incoloy 330 Tubing hardened nickel-based alloys and cold-worked solid nickel-based alloys offer many advantages such as high strength, toughness, low magnetic permeability and excellent corrosion resistance. Incoloy NCF Ra 330 Tubing Combines useful oxidation resistance and a fairly high melting point; it will tolerate rather extreme temperatures through 2,200°F (1,200°C). Inconel 330 Pipes was designed for appliances in elevated temperature industrial atmospheres where excellent resistance to the joint effects of thermal cycling and carburization are essential, such as the heat treat industry.

Incoloy 330 Pipes and Tubes – Equivalent Grades

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

| BS | En | No | AFNOR | ||||

| Incoloy 330 | N08330 | – | – | 1.4886 | – | – | – |

Incoloy 330 Pipes and Tubes Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Cu | N | |

| 330 | min. | – | – | 0.75 | – | – | 17.0 | – | 34.0 |

| max. | 0.08 | 2.0 | 1.50 | 0.030 | – | 20.0 | – | 37.0 | |

Incoloy 330 Pipe & Tubing Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 330 | – | – | – | – | – |

Incoloy 330 Seamless / Welded Pipes Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Forms of Incoloy 330 Pipe & Tubing in Stock

- Inconel 718 Seamless Pipes

- 718 Inconel EFW Tubing

- Incoloy 925 Hexagonal Pipe

- 718 Inconel Seamless Tubing

- ASTM B775 Inconel Welded Pipes

- B 444 Inconel Welded Tubes

- ASTM B444 Inconel 718 ERW Pipes

- B725 Rectangular Seamless Pipes

- UNS N07718 Inconel 718 Seamless Tubing

- 718 Alloy Welded Pipe

- Inconel 718 ERW Pipe

- Inconel 718EFW Pipe Manufacturer

- 718 Inconel Welded Pipe

- WERKSTOFF NR. 2.4668 Welded Pipe

- ASTM B670 718 Inconel Welded Pipes Supplier

- 718 Alloy Round Pipe Exporter

- UNS N07718 Round Pipe

- 718 Inconel Polished Pipe

Incoloy 330 Pipes and Tubes Price List

Request the latest Incoloy 330 Pipes Price List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement.

Mumbai, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Bhopal, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Vijayawada, Madurai, Varanasi, Meerut, Faridabad, Rajkot, Jamshedpur, Srinagar, Jabalpur, Asansol, Vasai Virar City, Allahabad, Dhanbad, Aurangabad, Amritsar, Jodhpur, Ranchi, Raipur, Kollam, Gwalior, Durg-Bhilainagar, Chandigarh, Tiruchirappalli, Kota

Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Afghanistan, Albania, Andorra, Austria, Bahrain, Bangladesh, Bhutan, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, North Korea, Netherlands, Norway, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Sri Lanka, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Vietnam, Yemen

Copyright © 2018 Aluminum Alloys.

Disclaimer : Inconel, Monel & Hastelloy are registered trademark of specific manufacturer, name are listed for the reference to help in identifying the grade.

India

India United States

United States Saudi Arabia

Saudi Arabia Kuwait

Kuwait Singapore

Singapore Malaysia

Malaysia UAE

UAE Germany

Germany Italy

Italy China

China UK

UK Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Brazil

Brazil France

France Taiwan

Taiwan Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela