Swage nipples, concentric swage, eccentric swage, npt/bspt threaded swage nipples manufacturer & suppliers mss-sp-95 standard, ASME b16.11, BS 3799, ASTM a105, a350-lf2, a106, a312, a234, a403, a182 (f304/304l, f316/316l) high pressure stainless steel swage nipples, carbon steel & alloy steel swage nipples manufacturer in India

Manufacturers, dealer, distributor, stockist & suppliers of Swage Nipples/Swage – MSS-SP-95

- Type of Pipe Nipples:-

- Hexagon Reducing Nipples

- Hexagon Nipples

- One End Threaded Nipple

- Both End Threaded Nipple

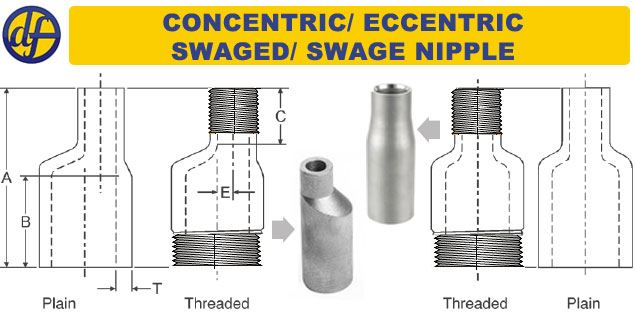

- Concentric Swaged Nipple

- Eccentric Swaged Nipple

- Dimensions, Wall Thickness and Weights of ANSI/ ASME Fittings to ASTM A403 / A815 ASME B16.9

- Dimensions, Wall Thickness and Weights of Fittings to ASME B16.9, ASME B16.28 and MSS SP75

- Factory-Made Wrought ASME/ANSI B16.9 A105 /A182 Pipe Fittings

- Swage Nipples/Swage – MSS-SP-95 Price in India » Please visit our Shop to buy Forged Fittings Online, price available material/ size wise in our shop

Swage Nipples/Swage – MSS-SP-95 manufacturing in Our Work Shop

Alloy Steel Tubes is an approved manufacturer of Swage Nipples/Swage – MSS-SP-95 to requirements of BVIS, IBR, BARC, DNV, BHEL & we are ISO 9001:2008, 14001:2004, OHSAS 18001:2007 certified company.

Alloy Steel Tubes is manufacturer of Swage Nipples, concentric and eccentric, are available in (T) current API threads, (B) beveled, (P) plain end (Square cut/socket weld), (G) ES groove or Victaulic (Std. Grv.) groove connections, or in any combination of such end finishes. Swage Nipples are manufactured accordance with MSS-SP-95 (Design Specification), ASME BS 3799, ASTM A105, A350-LF2, A106, A312, A234, A403, ASTM A182 (F304, F304L, F316, F316L). Swages or Swage Nipples are a type of pipe connection fitting used to go from one size tubing or casing to another.

specializes in manufacturing superior grade of steel like Carbon Steel, Alloy Steel, Stainless Steel 201/202, 304/304L, 310S, 316/316L, 317L, 321/321H, 347/347H, 904L, A234 WPB, A420 WPL6, A234 WP11/WP5, Inconel, Monel, Hastelloy, cupro nickel, nickel alloys, Duplex, A403 WP304L/316L – as per ASME B16.9, ASME B16.28. These Forged fittings have special quality finishing and duress for long life, high pressure and zero defects.

Hot selling grades:

Some of the common grade swage nipples include A234-WPB, A403-WP316, A403-WP304, and A420-WPL6 in size range of 1/4" through to 8" for concentric swage nipples and 1/4" to 4" for eccentric swage nipples.

Swage Nipples / Line Pipe Swages Benifits:

- Victaulic Grooves (Gruvlock) are distinguished by having Std. Grv. in the product description on all documentation.

- Unless otherwise specified concentric Swage Nipples will be supplied.

- Swage Nipples can be supplied with different schedule wall thickness at each end.

- Manufactured from A106 Grade B seamless pipe or cold drawn bar which is heat treated in accordance with ASTM A234-04 WPB.

- Choice of raw material dependent upon size and reduction.

We manufacture Pipe Nipples for end-users and ship worldwide. All steel pipe fittings are from ISO and PED approved mills- Raw Material Origin Indian MIlls & European Mills

Do you need your Swage Nipples/Swage – MSS-SP-95 shipped to you internationally? Not only do we ship all of our fittings & flanges globally, we will consolidate the order for you and ship it to the closest port near you. We have gained several Orders of Swage Nipples/Swage – MSS-SP-95 from countries like US, Canada, Chile, Brazil, UK, Italy, Venezuela, Belgium, France, Portugal, South Africa, Nigeria, Mexico, Chine, China, United Arab Emirates (UAE), Peru, Bahrain, Saudi Arabia, Qatar, Kuwait, Jordan, Malaysia, Thailand (Bangkok), Singapore, Indonesia, Sudan, Kazakhstan, Australia, Israel, Kenya, Russia, Tunisia, Vietnam, Colombia, Iran, Sri Lanka, etc.

Should you like to send you next enquiry for Swage Nipples/Swage – MSS-SP-95 to , please ![]() send us an email.

send us an email.

Pipe fitting surplus stock at Alloy Steel Tubes

Swage Nipples/Swage - MSS-SP-95 ,

stainless steel Pipe Nipples, carbon steel Pipe Nipples and alloy steel Pipe Nipples

Swage Nipples/Swage - MSS-SP-95 Production Range

Size: 1/8” to 8”, DN8 to DN200

Type: Concentric Swage Nipples, Eccentric Swage Nipples

Dimensions: MSS SP-95-2006, BS 3799

Connection Ends:

BBE = bevel both ends TBE = thread both ends

PBE = plain both ends GBE = grooved both ends

TXG = thread by groove TXB = thread by bevel

PXG = plain by groove BXT = bevel by thread

TLE: Thread large end PLE: Plain large end

BLE: Bevel large end PSE: Plain small end

BSE: Bevel small end TSE: Thread small end

Raw Materials: A106 Gr. B Seamless Pipes, A105/A105N Bars, A182 304/304L Bars, A182 316/316L Bars, A312 304/304L Seamless Pipes, Duplex Seamless Pipes, A312 316/316L Seamless Pipes, A350-LF2, Alloy Steel Seamless Pipes/Bars

Thickness: Standard, Extra Heavy, Schedule 160, or Double Extra Heavy

Ends: Beveled, Square Cut (for socket-weld), NPT/BSPT/BSP Threaded Swages, Customer Specification

Stainless Steel Swage Nipples/Swage – MSS-SP-95 :

202, 304, 304L, 304H, 316, 316L, 317, 317L, 321, 310, 347, 904L, 2205 Duplex

Carbon Steel Swage Nipples/Swage – MSS-SP-95 :

Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

NPT Threads conform to ASME B1.20.1

ASTM/ASME A105/SA105 The dimensions for forged carbon steel fittings conform to ASME B16.11

Alloy Steel Swage Nipples/Swage – MSS-SP-95 :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

A105/A105N Forged Fittings, A182 Forged Fittings

Nickel Alloy Swage Nipples/Swage – MSS-SP-95 :

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Duplex & Super Duplex Swage Nipples/Swage – MSS-SP-95 :

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Copper Nickel Swage Nipples/Swage – MSS-SP-95 :

CuNi10Fe1Mn, CuNi30Mn1Fe, Cupro nickel

Swage Nipples/Swage - MSS-SP-95 Test Certificates:

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report as per client specification.

Alloy Steel Tubes offer its Products with Third Party Inspection also. The Inspection Agency can be nominated by clients or Alloy Steel Tubes can be arrange the TPI by World reputed Agencies like Bureau Veritas, DNV, LLOYDS, ICB and many other. Our products are manufactured as per customer specifications and in accordance with international standards including American Standard (ASTM/ANSI), the British Standard (BS), and the DIN/European standard. NPT threads on Swage Nipples conform to ANSI/ASME B1.20.1. Swage Nipples/Swage – MSS-SP-95 are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. All our fittings are manufactured with tested raw materials and are supplied with NABL approved lab test reports. On demand, we can also provide, Hydro Testing Reports, Non Destructive Test Reports, or Destructive Test Reports.

Packaging & shipping:

Swage Nipples/Swage – MSS-SP-95 packing

emphasis on the packaging to ensure that there is no damage during transit the Swage Nipples/Swage – MSS-SP-95 are packed in wooden corrugated boxes foiled in bubble wraps & are marked with Grade, Lot No, Size, Degree and Alloy Steel Tubes Brand Mark. You can also contact us for customized marking.

Alloy Steel Tubes domestic network:

Mumbai, Ahmedabad, Chennai, Delhi, Bangalore

We also have our sales representative in Hyderabad, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi, Rajkot, Tamil Nadu, Maharashtra, Jaipur, Jabalpur, Vishakapatnam, Sholapur, Davangere, New Delhi, Kakinada, Belagavi, Udaipur, Guwahati, Ludhiana

CONCENTRIC SWAGED NIPPLES / ECCENTRIC SWAGED NIPPLES DIMENSIONS – BS 3799

Dimensions of swage nipples (BS 3799:1974)

Notes

Swaged Nipples can also be supplied to MSS or customers’ specifications