ASME/ ANSI B16.5 BLIND (BL) PIPE FLANGE MANUFACTURER IN INDIA, THREADED FORGED FLANGE AVAILABLE IN CARBON, ALLOY, STAINLESS STEEL, MANUFACTURING BLIND (BL) FLANGE IN ALL SIZE

Manufacturers, dealer, distributor, stockist & suppliers of ASME/ ANSI B16.5 Blind (BL) Pipe flange

Blind flange manufacturing & drilling in Our Work Shop

ANSI B16.5 FLANGE,Blind flange, CLASS 150, CLASS 300, CLASS 600, CLASS 900, CLASS1500, CLASS 2500 flange, flange, flange competitive prices, flange exporter, flange make, flange manufacturer, flange sales, forged flange, pipe flange, steel flange

is highly acclaimed manufacturer of pipe fittings & flange. Alloy Steel Tubes, produces the flange which meet all international quality standards such as DIN, EN1092-1, BS4504, ANSI, API, MSS, AWWA, UNI, JIS, SANS, GOST, NFE, ISO, AS, NS etc. We are manufacturing 75lbs, 150lbs, 300lbs, 600lbs, 900lbs, 1500lbs, 2500lbs, PN6, PN10, PN16, PN25, PN40, PN63, PN64, PN100, GOST 12820 and GOST 12821, PN0.6MPA, PN1.0MPA, PN1.6MPA, PN2.5MPA, PN4.0MPA, SANS1123 or SABS1123, 600kpa, 1000kpa, 1600kpa, 2500kpa, 4000kpa flange ratings as per application or client’s requirement. The ASME/ ANSI B16.5 Blind (BL) Pipe flange ratings are very important for flange application, correct flange rating will keep the application safe.

specializes in manufacturing high pressure, large diameter, high yield, and specialty flange. ASME/ ANSI B16.5 Blind (BL) Pipe flange are manufactured using superior grade of steel like Carbon Steel, Alloy Steel, Stainless Steel 201/202, 304/304L, 310S, 316/316L, 317L, 321/321H, 347/347H, 904L. These flange are most durable and manufactures to fit in different size of Pipes. The majority of our flange are manufactured from forged steel with a limited amount machined from bar stock. The forged construction provides higher strength and durability to provide long lasting performance in the application.

Alloy Steel Tubes offers competitive pricing and added convenience on flange accessories like flange packs, gaskets, flange connector, and flange bolts, and many other flange accessories which are designed to meet or exceed SAE J518 and ISO 6162. Our blind flange are available with raised or RTJ faces and also with female threads. Blind flange can be supplied with or without hub as per the customer requirements.

Do you need your ASME/ ANSI B16.5 Blind (BL) Pipe flange or other pipe flange shipped to you internationally? Not only do we ship all of our fittings & flange globally, we will consolidate the order for you and ship it to the closest port near you. We have gained several Orders of ASME/ ANSI B16.5 Blind (BL) Pipe flange from countries like US, Canada, Chile, Brazil, UK, Italy, Belgium, France, Portugal, South Africa, Nigeria, United Arab Emirates (UAE), Bahrain, Saudi Arabia, Qatar, Kuwait, Jordan, Malaysia, Thailand, Singapore, Indonesia, Sudan, Kazakhstan, Australia, Israel, Kenya, Russia, Tunisia, Vietnam, Colombia, Sri Lanka, etc.

Should you like to send you next enquiry for ASME/ ANSI B16.5 Blind (BL) Pipe flange to , please ![]() send us an email.

send us an email.

Pipe fitting surplus stock at Alloy Steel Tubes

Blind flange, ASME 16.5 Blind flange / BLRF flange/ BL Forged flange:

ASME/ ANSI B16.5 Blind (BL) Pipe flange latest price & specification

Price: US $0.2-10 / Piece

Size: 1/2" (15 NB) to 48" (1200NB)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, BS 4504, EN1092, UNI 2277/2278, DIN, Custom Drawings

Pressure Ratings: Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64, 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS etc.

Carbon Steel Blind flange: ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8

Stainless Steel Blind flange: ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L

Alloy Steel Blind flange: ASTM A182 F1, F5, F9, F11, F22, F91

Special Alloy Blind flange:

Nickel Alloys Blind flange: Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II).

Duplex, Super Duplex Blind flange: ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61, 2205 (UNS No. S31803), 2507 (UNS No.S32750)

Copper Alloy Blind flange: UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C71500 (Cu -Ni- 70/30)

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Coating/Surface Treatment: Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Value Added Services: CNC Machining, Customised flange

ASME/ ANSI B16.5 Blind (BL) Pipe flange Test Certificates:

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report as per client specification.

Alloy Steel Tubes offer its Products with Third Party Inspection also. The Inspection Agency can be nominated by clients or Alloy Steel Tubes can be arrange the TPI by World reputed Agencies like Bureau Veritas, DNV, LLOYDS, ICB and many other.

Packaging & shipping:

Blind flange packing

emphasis on the packaging to ensure that there is no damage during transit the ASME/ ANSI B16.5 Blind (BL) Pipe flange. The ASME/ ANSI B16.5 Blind (BL) Pipe flange are packed in wooden corrugated boxes foiled in bubble wraps & are marked with Grade, Lot No, Size, Degree and Alloy Steel Tubes Brand Mark. You can also contact us for customized marking.

ASME/ ANSI B16.5 BLIND FLANGES, BL FORGED FLANGES manufacturing materials:

| Dimensions | Base Material | Pressure Rating |

|---|---|---|

| ASME B16.5 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| API 605 | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| ASME B16.47series A & B | ASTM A182 (Forgings) ASTM A240 (Plate) | 150#. 300#. 400#. 600#. 900#. 1500#. 2500#. |

| EN1092-1 | ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. PN250. PN320. PN400. |

| BS4504 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | PN2.5. PN6. PN10. PN16. PN25. PN40. PN63. PN100. PN160. |

| BS10 | BS970 (Bar)ASTM A240 (Plate) ASTM A182 (Forgings) | Table D. Table E. Table F. Table H. Table J. Table K. Table R. Table S.Table T. |

Typical Stainless Steel 18/8 Grade Designations:

| ASTM | BS | DIN | EURONORM |

|---|---|---|---|

| 304 | 304S15 | X5 Cr Ni 18 10 | 1.4301 |

| 304L | 304S11 | X2 Cr Ni 18 9 | 1.4307 |

| 316 | 316S31 | X5 Cr Ni Mo 17 12 2 | 1.4401 |

| 316L | 316S11 | X2 Cr Ni Mo 17 13 2 | 1.4404 |

| 321 | 321S31 | X6 Cr Ni 18 10 | 1.4541 |

| 316Ti | 320S31 | X6 Cr Ni Mo Ti 17 12 2 | 1.4571 |

| SMO | 254SMO | X1 Cr Ni Mo Cu N 20 18 7 | 1.4547 |

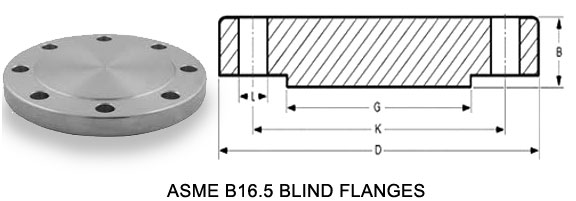

Blind flange Dimensions:

- ANSI ASME B16.48 Spectacle Blind flange Dimensions

- ANSI ASME B16.48 Class 150 Spectacle Blind Flange

- ANSI ASME B16.48 Class 300 Spectacle Blind Flange

- ANSI ASME B16.48 Class 600 Spectacle Blind Flange

- ANSI ASME B16.48 Class 900 Spectacle Blind Flange

- ANSI ASME B16.48 Class 1500 Spectacle Blind Flange

- ANSI ASME B16.48 Class 2500 Spectacle Blind Flange

- API 6A Type 6B WN & BL flange Dimensions

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flange

- API 6A Type 6B 3000 PSI Weld Neck & Blind Flange

- API 6A Type 6B 5000 PSI Weld Neck & Blind Flange

- API 6A Type 6BX WN & BL flange Dimensions

- API 6A Type 6BX 2000 PSI Blind Flange

- API 6A Type 6BX 3000 PSI Blind Flange

- API 6A Type 6BX 5000 PSI Blind Flange

- API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

- API 6A Type 6BX 15000 PSI Blind & Weld Neck Flanges

- API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges

- AWWA C207 SO & BL flange Dimensions

- Table 2 AWWA C207 Class B Ring & Blind Flange

- Table 2 AWWA C207 Class D Ring & Blind Flange

- Table 3 AWWA C207 Class D Hub Flanges

- Table 4 AWWA C207 Class E Hub Flanges

- Table 5 AWWA C207 Class E Ring & Blind Flange

- Table 6 AWWA C207 Class F Ring & Blind Flange

ANSI ASME B16.5 Blind flange Dimensions - ANSI ASME B16.5 Class 150 Blind Flanges

- ANSI ASME B16.5 Class 300 Blind Flanges

- ANSI ASME B16.5 Class 400 Blind Flanges

- ANSI ASME B16.5 Class 600 Blind Flanges

- ANSI ASME B16.5 Class 900 Blind Flanges

- ANSI ASME B16.5 Class 1500 Blind Flanges

- ANSI ASME B16.5 Class 2500 Blind Flanges

- DIN2527 Blind flange Dimensions

DIN2527 PN6 Blind flange

DIN2527 PN10 Blind flange

DIN2527 PN16 Blind flange

DIN2527 PN25 Blind flange

DIN2527 PN40 Blind flange

DIN2527 PN64 Blind flange

DIN2527 PN100 Blind flange - EN1092-1 Blind flange Type 05 Dimensions

EN1092-1 PN6 Blind flange Type 05

EN1092-1 PN10 Blind flange Type 05

EN1092-1 PN16 Blind flange Type 05

Alloy Steel Tubes domestic network:

Mumbai, Ahmedabad, Chennai, Delhi, Bangalore

We also have our sales representative in Davangere, New Delhi, Pune, Ranchi, Assam, Bhavnagar, Surat, Visakhapatnam, Bhubaneswar, Ankleshwar, Raipur, Jabalpur, Tamil Nadu, Maharashtra, Bhiwandi, Bikaner, Belagavi, Guwahati, Hyderabad, Vishakapatnam, Thane, Kakinada, Mysore, Siliguri, Salem, Udaipur, Faridabad, Aurangabad, Sholapur, Ludhiana, Kolkata, Bhilai, Nagpur, Mangalore, Rajkot, Jaipur, Indore, Tirupur, Coimbatore, Bhopal, Kochi (Cochin), Vadodra, Nashik

Dimensions of Blind flange ASME B16.5:

NPS ½

| Class | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| Diameter – D | 90 | 95 | 95 | 95 | 120 | 120 | 135 |

| Height – B | 9.6 | 12.7 | 14.3 | 14.3 | 22.3 | 22.3 | 30.2 |

| 11.2 | 14.3 | 20.7 | 20.7 | 28.7 | 28.7 | 36.6 | |

| Diameter – G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 |

| Diameter – K | 60.3 | 66.7 | 66.7 | 66.7 | 82.6 | 82.6 | 88.9 |

| Bolt Holes | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Diameter – L | 15.9 | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | 22.2 |

| Stud Bolts Diameter x Length | |||||||

| Diameter (in) | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

| Length (mm) | 55 | 65 | 75 | 75 | 110 | 110 | 120 |

Dimensional Tolerances of Blind flange ASME B16.5:

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter not applicable |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore not applicable |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |