Threaded Swage Nipple Manufacturer

Threaded Swage Nipple Dimensions, ASME B16.11 Threaded Eccentric Swage Nipple Supplier

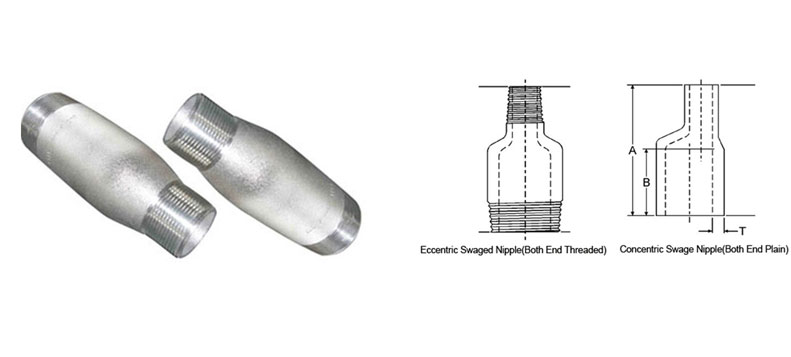

Concentric Swage Nipple, Swage Nipple Threaded Both Ends, Swage Nipple Threaded One End, Threaded Swage Nipple Weight

BS3799 Forged Steel Threaded Swage Nipple, NPT Threaded Swage Nipple Size Chart, Threaded Swage Nipple Price

Threaded Swage Nipple

Threaded Eccentric Swage Nipple

Table Of Content

All swage nipples manufactured by Ally International Co are either manufactured from seamless pipe or bar material and have suitable working pressure equivalent to straight seamless pipes. We use high quality raw materials (steel pipes, bar stock) for manufacturing stainless steel swage nipples and carbon steel swage nipples. The raw materials we use are fully traceable to the mill source through our MTR reports. Our products are manufactured as per customer specifications and in accordance with international standards including American Standard (ASTM/ANSI), the British Standard (BS), and the DIN/European standard. NPT threads on Swage Nipples conform to ANSI/ASME B1.20.1.Our swage nipple products are supplied with EN 10204 3.1 Test Certification, with complete details on the chemical and physical properties of the materials. They are permanently marked with size, schedule, grade, and heat code.

An ISO 9001:2015 Certified Company,Ally International Co is experts in manufacturing swage nipples in India. Swage Nipples are manufactured accordance with MSS-SP-95 (Design Specification), ASME BS 3799, ASTM A105, A350-LF2, A106, A312, A234, A403, ASTM A182 (F304, F304L, F316, F316L). Swages or Swage Nipples are a type of pipe connection fitting used to go from one size tubing or casing to another. Some of the common grade swage nipples we manufacture include A234-WPB, A403-WP316, A403-WP304, and A420-WPL6 in size range of 1/4″ through to 8″ forconcentric swage nipplesand 1/4″ to 4” for eccentric swage nipples. We can offer Swage Nipples with plain, beveled or threaded ends. Thickness and outside diameters of swage nipples shall correspond to those of the appropriate nominal pipe size. Swage nipples are offered in threaded ends per ASME B1.20.1 and beveled ends per ASME B16.25.

Swage Nipples MSS-SP-95 Design Specification – Dimensional Standard for Stainless Steel, Carbon Steel, Alloy Steel Swage Nipples

Swage Nipples BS3799 Design Specification – Dimensional Standard for Stainless Steel, Carbon Steel, Alloy Steel Swage Nipples

Stock Of Threaded Swage Nipple Pressure Ratings, Threaded Swage Nipple Galavanized, Threaded Swage Nipple ASME B16.11

High Quality Threaded Swage Nipple, Threaded Swage Nipple Eccentric Swage, Threaded Swage Nipple Fitting, Threaded Swage Nipple High Pressure, Threaded Swage Nipple in India

Threaded Swage Nipple Standrad

| Size | 1/8” to 8”, DN8 to DN200 |

| Type | Concentric Swage Nipples, Eccentric Swage Nipples |

| Dimensions | MSS SP-95-2006, BS 3799 |

| Raw Materials | A106 Gr. B Seamless Pipes, A105/A105N Bars, A182 304/304L Bars, A182 316/316L Bars, A312 304/304L Seamless Pipes, Duplex Seamless Pipes, A312 316/316L Seamless Pipes, A350-LF2, Alloy Steel Seamless Pipes/Bars |

| Material Specifications | ASTM A105, A350 LF2, ASTM A182 (F304,F304L,F316,F316L,F304H,F316H,F317L,F321,F11,F22,F91) |

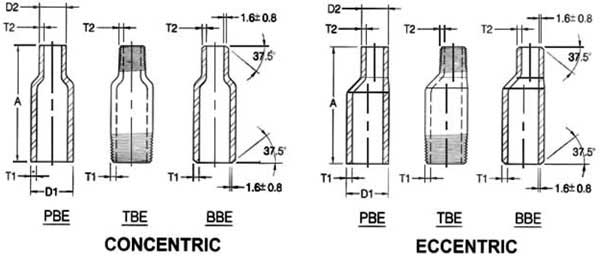

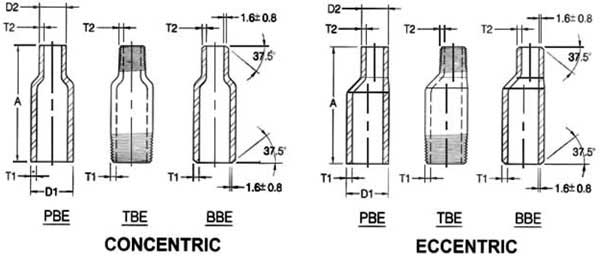

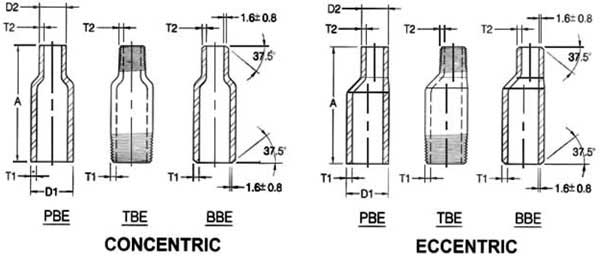

| Connection Ends | PBE: Plain both ends, BBE: Bevel both ends, TBE: Thread both ends PSE: Plain small end, BSE: Bevel small end, TSE: Thread small end PLE: Plain large end, BLE: Bevel large end, TLE: Thread large end Thickness: Standard, Extra Heavy, Schedule 160, or Double Extra Heavy |

| Ends | Beveled, Square Cut (for socket-weld), NPT/BSPT/BSP Threaded Swages, Customer Specification |

| Test Certificates | EN 10204 3.1, Raw Material Certificates Available, Destructive & Non Destructive Testing (NDT) Reports from NABL Approved Labs |

| Material Finish | Electro-Galvanized Coating, Black Finish, Blackodising Finish, Sand Blasting, or Pickled Finish in case of Stainless Steel Swage Nipples |

ASME B16.11 Threaded Swage Nipple Dimensions Standrad

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Swage Nipple Material

ASME B16.11 Stainless Steel Forged Threaded Swage Nipple :

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel ASME B16.11 Forged Threaded Swage Nipple :

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel ASME B16.11 Forged Threaded Swage Nipple:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

ASME B16.11 Alloy Steel Forged Threaded Swage Nipple:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

ASME B16.11 Copper Alloy Steel Forged Threaded Swage Nipple: ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30)

Nickel Alloy Forged Threaded ASME B16.11 Swage Nipple:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

ANSI/ASME B16.11 THREADED SWAGE NIPPLE DIMENSIONS

Nominal Pipe Size (NPS) |

Outside Diameter |

End To End “A” |

Wall Thickness |

||||||||

Large End D1 |

Small End D2 |

T1 |

T2 |

||||||||

Sch40 (STD) |

Sch80 (XS) |

Sch160 |

XXS |

Sch40 (STD) |

Sch80 (XS) |

Sch160 |

XXS |

||||

1/4”x1/8” |

13.7 |

10.3 |

57 |

2.2 |

3.0 |

3.7 |

6.1 |

1.7 |

2.4 |

|

|

3/8”x1/8” |

17.1 |

10.3 |

64 |

2.3 |

3.2 |

4.0 |

6.4 |

1.7 |

2.4 |

|

|

3/8”x1/4” |

17.1 |

13.7 |

64 |

2.3 |

3.2 |

4.0 |

6.4 |

2.2 |

3.0 |

|

|

1/2”x1/8” |

21.3 |

10.3 |

70 |

2.8 |

3.7 |

4.8 |

7.5 |

1.7 |

2.4 |

|

|

1/2”x1/4” |

21.3 |

13.7 |

70 |

2.8 |

3.7 |

4.8 |

7.5 |

2.2 |

3.0 |

|

|

1/2”x3/8” |

21.3 |

17.1 |

70 |

2.8 |

3.7 |

4.8 |

7.5 |

2.3 |

3.2 |

|

|

3/4”x1/8” |

26.7 |

10.3 |

76 |

2.9 |

3.9 |

5.6 |

7.8 |

1.7 |

2.4 |

|

|

3/4’x1/4” |

26.7 |

13.7 |

76 |

2.9 |

3.9 |

5.6 |

7.8 |

2.2 |

3.0 |

|

|

3/4”x3/8” |

26.7 |

17.1 |

76 |

2.9 |

3.9 |

5.6 |

7.8 |

2.3 |

3.2 |

|

|

3/4”x1/2” |

26.7 |

21.3 |

76 |

2.9 |

3.9 |

5.6 |

7.8 |

2.8 |

3.7 |

4.8 |

7.5 |

1”x1/8” |

33.4 |

10.3 |

89 |

3.4 |

4.5 |

6.4 |

9.1 |

1.7 |

2.4 |

|

|

1”x1/4” |

33.4 |

13.7 |

89 |

3.4 |

4.5 |

6.4 |

9.1 |

2.2 |

3.0 |

|

|

1”x3/8” |

33.4 |

17.1 |

89 |

3.4 |

4.5 |

6.4 |

9.1 |

2.3 |

3.2 |

|

|

1”x1/2” |

33.4 |

21.3 |

89 |

3.4 |

4.5 |

6.4 |

9.1 |

2.8 |

3.7 |

4.8 |

7.5 |

1”x3/4” |

33.4 |

26.7 |

89 |

3.4 |

4.5 |

6.4 |

9.1 |

2.9 |

3.9 |

5.6 |

7.8 |

1-1/4”x1/8” |

42.2 |

10.3 |

102 |

3.6 |

4.9 |

6.4 |

9.7 |

1.7 |

2.4 |

|

|

1-1/4”x1/4” |

42.2 |

13.7 |

102 |

3.6 |

4.9 |

6.4 |

9.7 |

2.2 |

3.0 |

|

|

1-1/4”x3/8” |

42.2 |

17.1 |

102 |

3.6 |

4.9 |

6.4 |

9.7 |

2.3 |

3.2 |

|

|

1-1/4”x1/2” |

42.2 |

21.3 |

102 |

3.6 |

4.9 |

6.4 |

9.7 |

2.8 |

3.7 |

4.8 |

7.5 |

1-1/4”x3/4” |

42.2 |

26.7 |

102 |

3.6 |

4.9 |

6.4 |

9.7 |

2.9 |

3.9 |

5.6 |

7.8 |

1-1/4”x1” |

42.2 |

33.4 |

102 |

3.6 |

4.9 |

6.4 |

9.7 |

3.4 |

4.5 |

6.4 |

9.1 |

1-1/2”x1/8” |

48.3 |

10.3 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

1.7 |

2.4 |

|

|

1-1/2”x1/4” |

48.3 |

13.7 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

2.2 |

3.0 |

|

|

1-1/2”x3/8” |

48.3 |

17.1 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

2.3 |

3.2 |

|

|

1-1/2”x1/2” |

48.3 |

21.3 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

2.8 |

3.7 |

4.8 |

7.5 |

1-1/2”x3/4” |

48.3 |

26.7 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

2.9 |

3.9 |

5.6 |

7.8 |

1-1/2”x1” |

48.3 |

33.4 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

3.4 |

4.5 |

6.4 |

9.1 |

1-1/2”x1-1/4” |

48.3 |

42.2 |

114 |

3.7 |

5.1 |

7.1 |

10.2 |

3.6 |

4.9 |

6.4 |

9.7 |

2”x1/8” |

60.3 |

10.3 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

1.7 |

2.4 |

|

|

2”x1/4” |

60.3 |

13.7 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

2.2 |

3.0 |

|

|

2”x3/8” |

60.3 |

17.1 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

2.3 |

3.2 |

|

|

2”x1/2” |

60.3 |

21.3 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

2.8 |

3.7 |

4.8 |

7.5 |

Nominal Pipe Size (NPS) |

Outside Diameter |

End To End “A” |

Wall Thickness |

||||||||

Large End D1 |

Small End D2 |

T1 |

T2 |

||||||||

Sch40 (STD) |

Sch80 (XS) |

Sch160 |

XXS |

Sch40 (STD) |

Sch80 (XS) |

Sch160 |

XXS |

||||

2”x3/4” |

60.3 |

26.7 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

2.9 |

3.9 |

5.6 |

7.8 |

2”x1” |

60.3 |

33.4 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

3.4 |

4.5 |

6.4 |

9.1 |

2”x1-1/4” |

60.3 |

42.2 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

3.6 |

4.9 |

6.4 |

9.7 |

2”x1-1/2” |

60.3 |

48.3 |

165 |

3.9 |

5.5 |

8.7 |

11.1 |

3.7 |

5.1 |

7.1 |

10.2 |

2-1/2”x1/8” |

73.0 |

10.3 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

1.7 |

2.4 |

|

|

2-1/2”x1/4” |

73.0 |

13.7 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

2.2 |

3.0 |

|

|

2-1/2”x3/8” |

73.0 |

17.1 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

2.3 |

3.2 |

|

|

2-1/2”x1/2” |

73.0 |

21.3 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

2.8 |

3.7 |

4.8 |

7.5 |

2-1/2”x3/4” |

73.0 |

26.7 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

2.9 |

3.9 |

5.6 |

7.8 |

2-1/2”x1” |

73.0 |

33.4 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

3.4 |

4.5 |

6.4 |

9.1 |

2-1/2”x1-1/4” |

73.0 |

42.2 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

3.6 |

4.9 |

6.4 |

9.7 |

2-1/2”x1-1/2” |

73.0 |

48.3 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

3.7 |

5.1 |

7.1 |

10.2 |

2-1/2”x2” |

73.0 |

60.3 |

178 |

5.2 |

7.0 |

9.5 |

14.0 |

3.9 |

5.5 |

8.7 |

11.1 |

3”x1/8” |

88.9 |

10.3 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

1.7 |

2.4 |

3.2 |

4.8 |

3”x1/4” |

88.9 |

13.7 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

2.2 |

3.0 |

3.7 |

6.1 |

3”x3/8” |

88.9 |

17.1 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

2.3 |

3.2 |

4.0 |

6.4 |

3”x1/2” |

88.9 |

21.3 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

2.8 |

3.7 |

4.8 |

7.5 |

3”x3/4” |

88.9 |

26.7 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

2.9 |

3.9 |

5.6 |

7.8 |

3”x1” |

88.9 |

33.4 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

3.4 |

4.5 |

6.4 |

9.1 |

3”x1-1/4” |

88.9 |

42.2 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

3.6 |

4.9 |

6.4 |

9.7 |

3”x1-1/2” |

88.9 |

48.3 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

3.7 |

5.1 |

7.1 |

10.2 |

3”x2” |

88.9 |

60.3 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

3.9 |

5.5 |

8.7 |

11.1 |

3”x2-1/2” |

88.9 |

73.0 |

203 |

5.5 |

7.6 |

11.1 |

15.2 |

5.2 |

7.0 |

9.5 |

14.0 |

3-1/2”x1/8” |

101.6 |

10.3 |

203 |

5.7 |

8.1 |

|

|

1.7 |

2.4 |

|

|

3-1/2”x1/4” |

101.6 |

13.7 |

203 |

5.7 |

8.1 |

|

|

2.2 |

3.0 |

|

|

3-1/2”x3/8” |

101.6 |

17.1 |

203 |

5.7 |

8.1 |

|

|

2.3 |

3.2 |

|

|

3-1/2”x1/2” |

101.6 |

21.3 |

203 |

5.7 |

8.1 |

|

|

2.8 |

3.7 |

4.8 |

7.5 |

3-1/2”x3/4” |

101.6 |

26.7 |

203 |

5.7 |

8.1 |

|

|

2.9 |

3.9 |

5.6 |

7.8 |

3-1/2”x1” |

101.6 |

33.4 |

203 |

5.7 |

8.1 |

|

|

3.4 |

4.5 |

6.4 |

9.1 |

3-1/2”x1-1/4” |

101.6 |

42.2 |

203 |

5.7 |

8.1 |

|

|

3.6 |

4.9 |

6.4 |

9.7 |

Nominal Pipe Size (NPS) |

Outside Diameter |

End To End |

Wall Thickness |

||||||||

Large End D1 |

Small End D2 |

T1 |

T2 |

||||||||

Sch40 (STD) |

Sch80 (XS) |

Sch160 |

XXS |

Sch40 (STD) |

Sch80 (XS) |

Sch160 |

XXS |

||||

3-1/2”x1-1/2” |

101.6 |

48.3 |

203 |

5.7 |

8.1 |

|

|

3.7 |

5.1 |

7.1 |

10.2 |

3-1/2”x2” |

101.6 |

60.3 |

203 |

5.7 |

8.1 |

|

|

3.9 |

5.5 |

8.7 |

11.1 |

3-1/2”x2-1/2” |

101.6 |

73.0 |

203 |

5.7 |

8.1 |

|

|

5.2 |

7.0 |

9.5 |

14.0 |

3-1/2”x3” |

101.6 |

88.9 |

203 |

5.7 |

8.1 |

|

|

5.5 |

7.6 |

11.1 |

15.2 |

4”x1/4” |

114.3 |

13.7 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

2.2 |

3.0 |

|

|

4”x3/8” |

114.3 |

17.1 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

2.3 |

3.2 |

|

|

4”x1/2” |

114.3 |

21.3 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

2.8 |

3.7 |

4.8 |

7.5 |

4”x3/4” |

114.3 |

26.7 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

2.9 |

3.9 |

5.6 |

7.8 |

4”x1” |

114.3 |

33.4 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

3.4 |

4.5 |

6.4 |

9.1 |

4”x1-1/4” |

114.3 |

42.2 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

3.6 |

4.9 |

6.4 |

9.7 |

4”x1-1/2” |

114.3 |

48.3 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

3.7 |

5.1 |

7.1 |

10.2 |

4”x2” |

114.3 |

60.3 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

3.9 |

5.5 |

8.7 |

11.1 |

4”x2-1/2” |

114.3 |

73.0 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

5.2 |

7.0 |

9.5 |

14.0 |

4”x3” |

114.3 |

88.9 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

5.5 |

7.6 |

11.1 |

15.2 |

4”x3-1/2” |

114.3 |

101.6 |

229 |

6.0 |

8.6 |

13.5 |

17.1 |

5.7 |

8.1 |

|

|

- Dimensions in Millimeters.

- Wall Thickness:T1 & T2 in accordance with ASME B36.10M

PBE:Plain Both Ends |

BBE:Bevel Both Ends |

TBE:Thread Both Ends |

PSE:Plain Small End |

BSE:Bevel Small End |

TSE:Thread Small End |

PLE:Plain Large End |

BLE:Bevel Large End |

TLE:Thread Large End |

Dimensional Tolerance of Swaged Nipple

Nominal Pipe Size (inch) |

Overall Length (mm) |

Outside diameter at end |

Wall Thickness (prior to threading or grooving) |

|

Square Cut Ends (mm) |

Other End Connection (mm) |

|||

1/8” to 3/8” |

± 1.5 |

+ 0.40 |

± 0.80 |

Not less than 87.5% of nominal wall thickness |

1/2” to 1-1/2” |

± 1.5 |

+ 0.40 |

+ 1.50 |

|

2” to 2-1/2” |

± 3.0 |

± 0.80 |

+ 1.50 |

|

3” to 4” |

± 3.0 |

± 0.80 |

± 1.50 |

|

Seamless Swage Nipples

| I.D. or Nominal Size | Outside Diameter | Length | ||

| NU | EUE | NU | EUE | |

| 1/8 | — | — | — | — |

| 1/4 | .540 | — | 2 1/4 | — |

| 3/8 | .675 | — | 2 1/2 | — |

| 1/2 | .840 | — | 2 3/4 | — |

| 3/4 | 1.050 | — | 3 | — |

| 1 | 1.315 | 1.469 | 3 1/2 | 4 1/2 |

| 1 1/4 | 1.660 | 1.812 | 4 | 6 |

| I.D. or Nominal Size | Outside Diameter | Length | ||

| NU | EUE | NU | EUE | |

| 1 1/2 | 1.900 | 2.094 | 4 1/2 | 6 |

| 2 | 2.375 | 2.594 | 6 1/2 | 8 |

| 2 1/2 | 2.875 | 3.094 | 7 | 8 |

| 3 | 3.500 | 3.750 | 8 | 8 |

| 3 1/2 | 4.000 | 4.250 | 8 | 8 |

| 4 | 4.500 | 4.750 | 9 | 9 |

ASME B16.11 Swage Nipple Price

ASME B16.11 Threaded Swage Nipple Price: $120.45 / eachANSI B16.11 Swage Nipple Price: $10.14 / each

Threaded Swage Nipple Price: $8.35 / each

ASME B16.11 Threaded Swage Nipple Supplying to Following Regions & Countries:

| AFRICA Nigeria Algeria Angola Tanzania Libya Egypt Sudan Equatorial Guinea The Republic Of Congo Gabon NORTH AMERICA Usa Canada Mexico Costa Rica Trinidad And Tobago Jamaica Denmark |

MIDDLE EAST ASIA Saudi Arabia Iran Iraq Uae Qatar Bahrain Oman Kuwait Turkey Jordan SOUTH AMERICA Argentina Bolivia Brazil Chile Venezuela Colombia Ecuador Guyana Paraguay Uruguay |

EUROPE Norway Germany France Italy Uk Spain Netherland Belgium Greece Czech Republic Portugal Hungary SOUTH AFRICA |

ASIA India Singapore Malaysia Indonesia Thailand Vietnam South Korea Japan Sri Lanka Maldives Bangladesh Mayanmar Taiwan Cambodia |